Fenix III seed meter

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

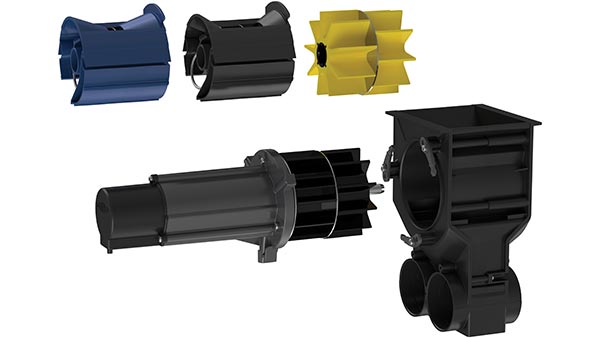

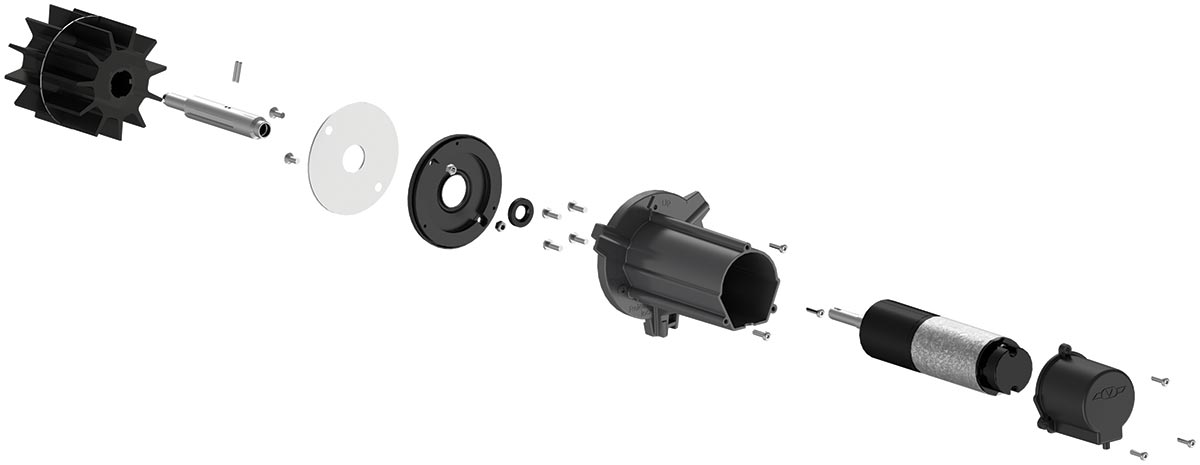

The unique Väderstad Fenix III seed metering system is engineered for exceptionally precise seeding, reliable performance and easy maintenance, year after year.

Precision in detail

An integrated, seamless design ensures the consistent flow of all products. The motor, rollers, housing, inlets, and outlets work together flawlessly. This design ensures the meter can handle difficult products such as inoculants, micro nutrients, and problematic seeds.

A high torque 40-watt motor drives constant product flow, and four unique roller designs make it possible to meter a wide range of seed and products at a variety of rates.

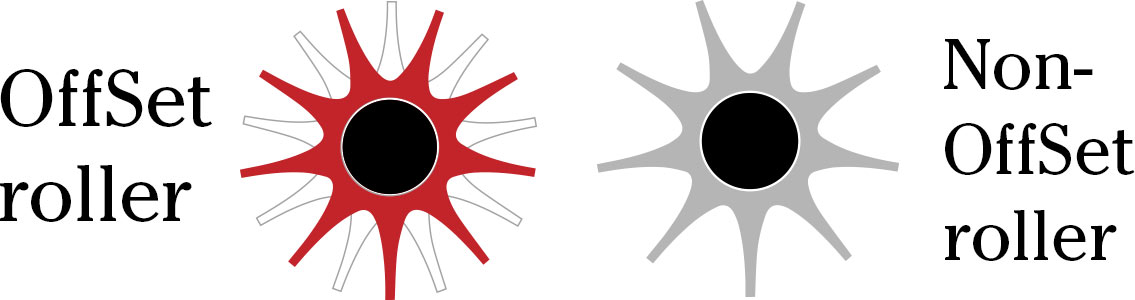

OffSet for even product flow

OffSet roller flutes and an angled outlet ensure smooth, constant product flow. Fenix III rollers do not fill across the entire width of the inlet at the same time. Instead, they alternate feeding from one side of the roller to the other. By angling the meter outlet, the product is channelled. The centre releases first, then the side.

Jamming is prevented by a unique levelling lip at the top of the meter housing. The lip works in conjunction with the flexible roller flutes, ensuring a consistent rate of delivery.

Fenix III OffSet rollers eliminate pulsing of products through the meters, prevent jamming and ensure even seeding rates.

OffSet rollers vs. non-OffSet rollers

OffSet roller

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Non-OffSet roller

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Reliable metering

A gearbox with a 64:1 reduction allows the Fenix III to run at lower RPMs and seed at a wide range of rates. Placing the motor outside the meter housing prevents product contamination. Driving the meter with a high torque 40-watt motor ensures consistent seeding without jamming.

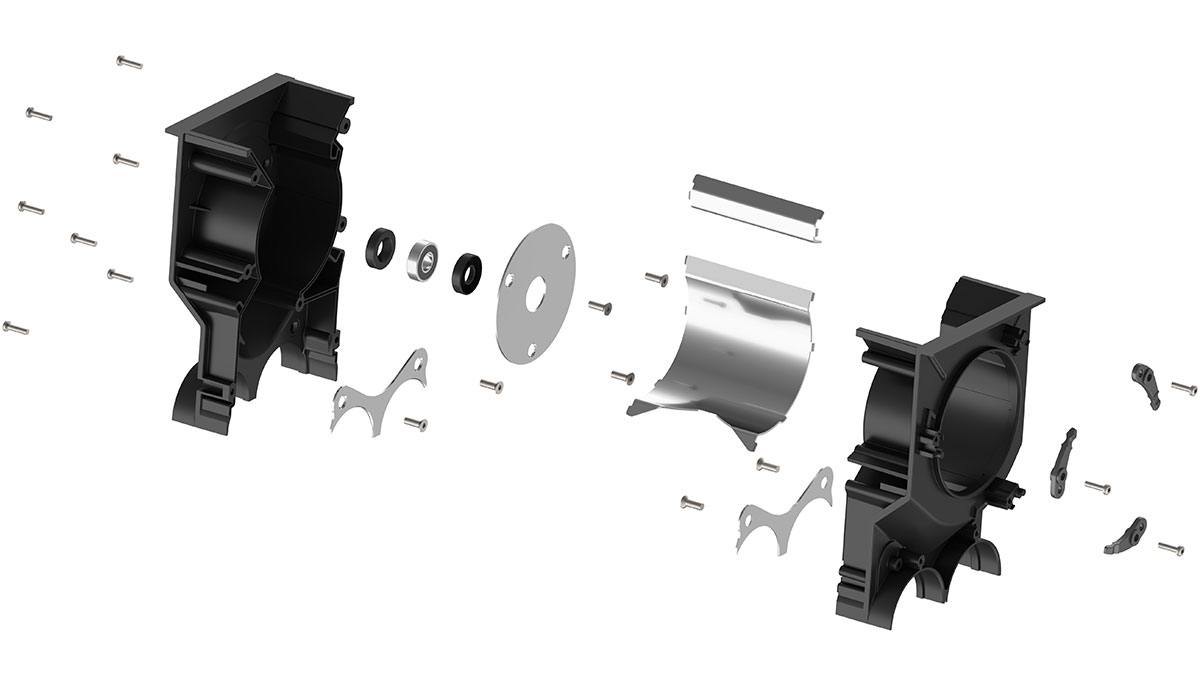

Machining the central shaft on both sides prevents wear and increase shaft and roller life. Polyurethane rollers increase flexibility and ensure durability.

Robust and durable

Stainless steel lining on the rear wall and feed side of the meter housing ensure a robust, durable meter able to withstand a wide variety of abrasive products. Securing the central shaft inside the meter housing and inside the gearbox with stainless steel bearings keeps the shaft secure and stable as the roller rotates. The bearing inside the meter housing is double sealed against wear and contamination.

Simple operation

The motors are easy to remove and can be quickly reinserted into the housing. The rollers are also quick and easy to remove and replace. Machined motor shafts ensure that rollers can only be installed in the correct direction.

Cleaning is easy, thanks to an anti-static polymer construction and stainless-steel lining. With only a few parts and no grease zerks, maintenance is simple.