Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Ultra-shallow tillage with CrossCutter Disc

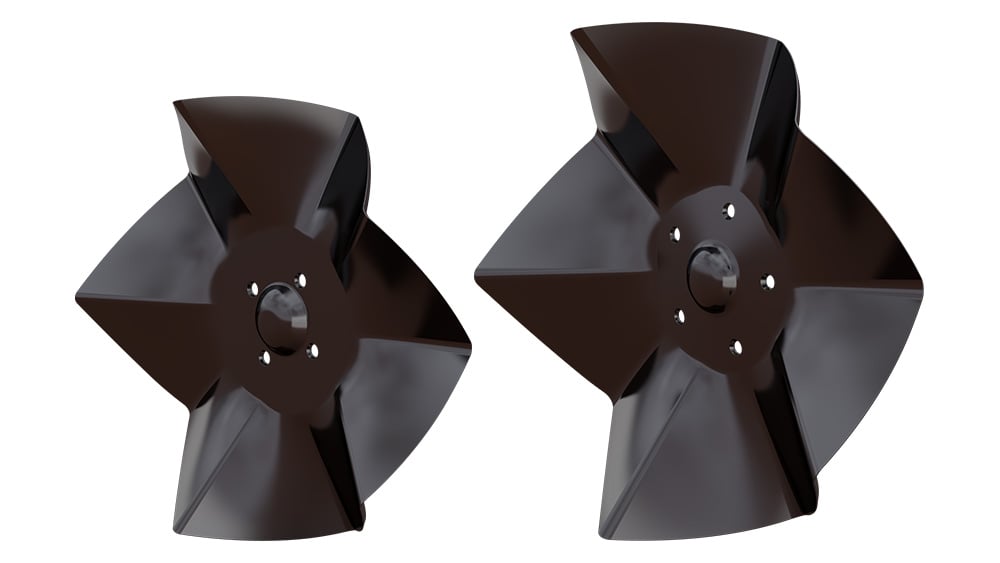

CrossCutter Disc provides full cultivation at only 2-3cm working depth. It’s unique cutting intensity crushes, chops and mulches in one single pass. CrossCutter Disc performs outstanding in oilseed rape stubble and in cover crops, while also enabling great advantages in grain stubble and on ploughed land.

Ultra-shallow tillage with full cultivation |

Less fuel – higher speed |

Don’t waste time at your stale seedbed |

Mulching of cover crops |

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Full cultivation at ultra-shallow working depth

CrossCutter Disc works very intensively with a low horsepower requirement, at ultra-shallow working depth and high speed up to 20km/h. CrossCutter Disc can be fitted to the versatile disc cultivator Väderstad Carrier, available from 3.0 to 12.25m working width. Equipping Carrier with CrossCutter Disc enables a new work horizon in the agronomic toolbox.

CrossCutter Disc

The original ultra-shallow tillage specialist.

Available as 450mm (2-3cm work depth) and 510mm (3-5cm work depth).

Cleaner fields with increased yield potential

The topic field hygiene focuses on the post-harvest management of oil seed rape, cereals and other crops where the goal is to bring the seedbank to germination and the residues to decompose as fast as possible. A reduced seedbank improves the competitiveness of the following crop and may reduce the cost for herbicides. Ultra shallow tillage is also tested as a partial solution in case of the loss of glyphosate.

Fight weeds efficient

Many weed seeds, such as blackgrass are triggered by light. If buried too deep, they can stay dormant in the soil for many years. The CrossCutter disc throws the material upwards allowing it to sort when falling down. The lightest material, such as weed seeds, will then land on the surface where they encounter optimal conditions for a fast germinating. The stale seedbed can later be eliminated with a second pass, to provide great field hygiene for the next crop.

Don’t waste time at your stale seedbed

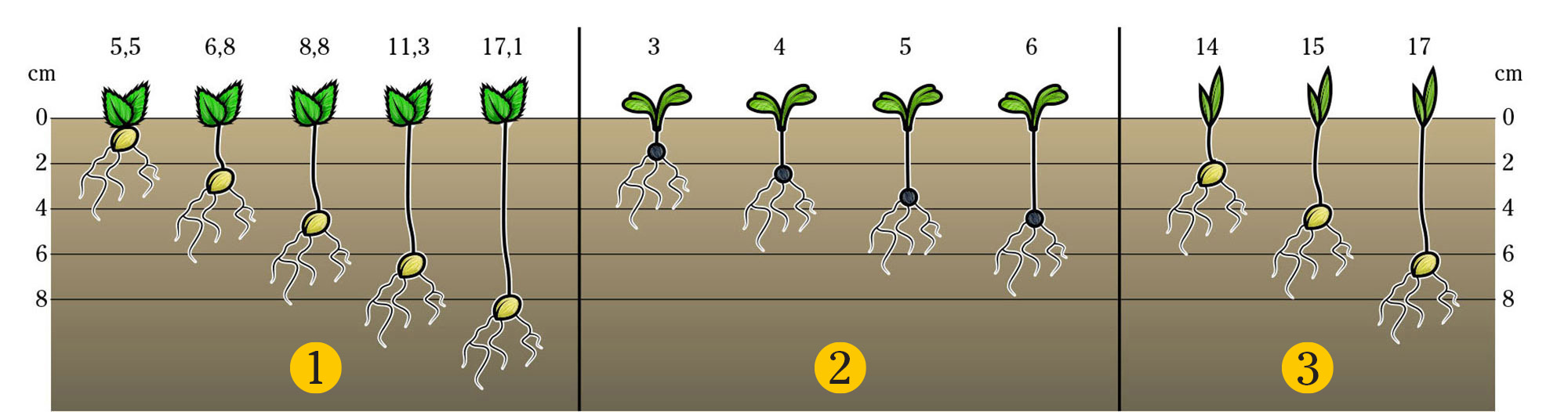

According to research, the depth of seeds of oilseed rape, weeds and grain directly affects the time needed for the seeds in the stale seedbed to germinate, grow and emerge. By reducing the time spent on waiting for the stale seedbed to emerge enough to be eliminated, means that the following crop can be drilled sooner. Alternatively, this additional time provides great opportunities for increasing the yield potential by conducting value-adding field work before the next crop establishment.

CrossCutter Disc gives a better incorporation and mulching

After cover crops and silage maize the mulching and incorporation of crop residues is crucial for success. To increase the cultivation intensity, CrossCutter Disc can be combined with the knife roller CrossCutter Knife. Using an aggressive packer such as a SteelRunner will further improve the cultivation effect.

Complete cover crop elimination

When terminating a standing cover crop, a full cut-out at ultra-shallow working depth provides high capacity and great agronomical benefits. Working intensively at 0-3cm depth, crushes and mulches the cover crops without mixing the residues in depth. After one pass, the cover crops stems are crushed and access points for microorganisms are created. This fully eliminates the cover crop, while also minimising the risk for problems in the following crop.

Excellent after silage maize

After silage maize two main objectives needs to be fulfilled; destroy the habitat for the European corn bohrer and avoid the creation of mycotoxins that can be transferred to the following crop. CrossCutter Disc will achieve both tasks at a very low cost, increasing the breakdown rate compared to chopping the residues. A benefit compared to a mulcher, is that CrossCutter Disc also handles the residues in the wheel tracks.

Moisture and structure conservation – When less is more

By cutting in its entire working horizon, CrossCutter Disc completely breaks the capillarity. This conserves valuable ground moisture for the coming crop.

The ultra-shallow working depth ensures that a minimum amount of soil is dried out, while the high amount of residues left in the topsoil helps reflecting sunlight to further conserve moisture.

Reduced erosion

By working ultra-shallow, a minimal amount of soil gets loosened and vulnerable to erosion. This is crucial in hilly conditions as well as on farming conditions where wind erosion appears. The large amount of residues mixed in the topsoil absorbs the impact of raindrops which prevents runoff as well as eliminates the risk of capping the soil.

Minimal disturbance of soil fauna

The ultra-shallow tillage in the dry topsoil leads to minimal earthworm losses and the following capillarity cut increases the soil moisture making the earthworms more active.

Leaving residues in the topsoil benefits the earthworm activity, increasing the rate of decomposition even further. This at the same time as the earthworms fertilises the soil and gives the coming crop better conditions.

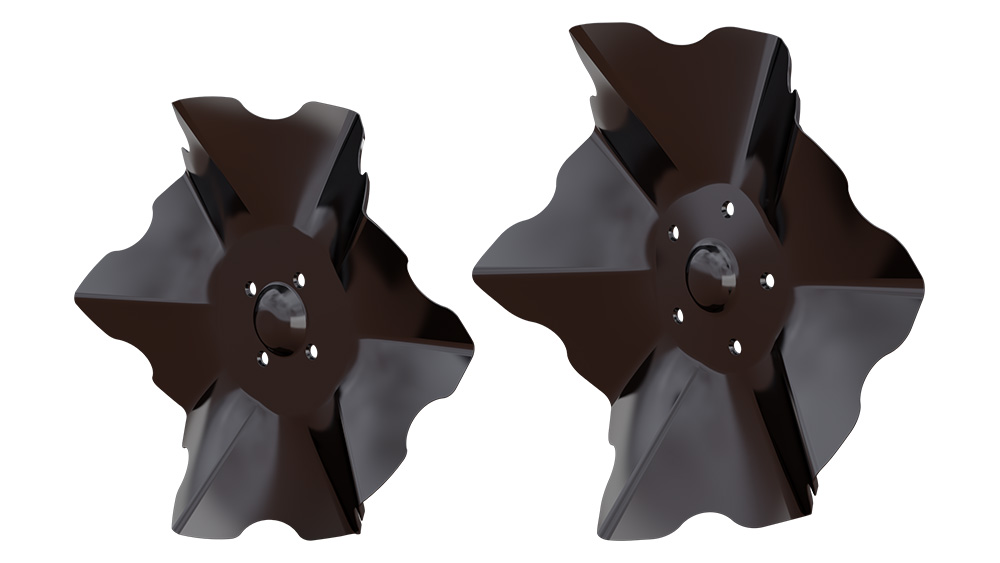

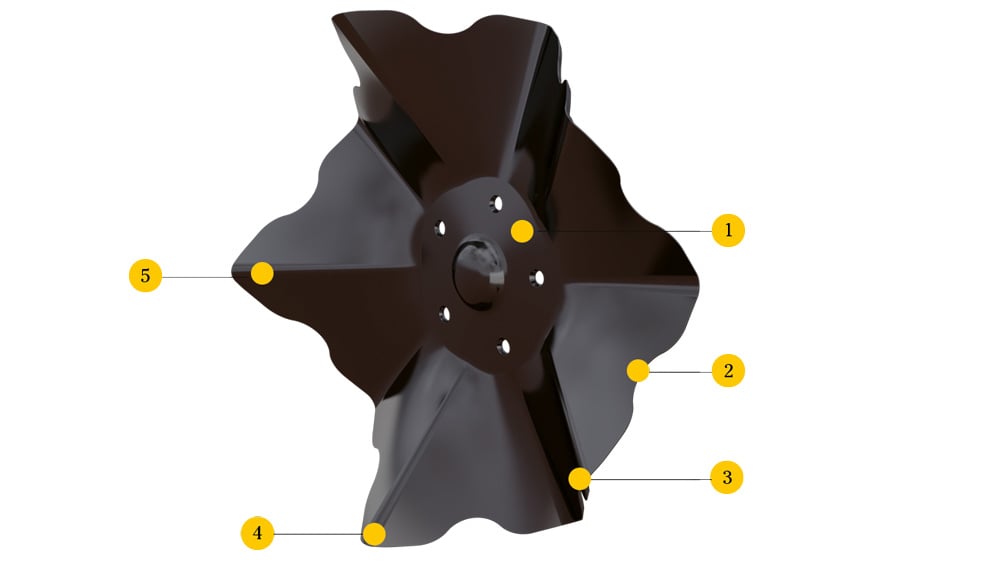

CrossCutter Disc Aggressive

The newest addition to the CrossCutter Disc family, the CrossCutter Disc Aggressive is developed for challenging field conditions. With its unique shape and sharpened TrueCut cut outs, CrossCutter Disc Aggressive excels in hard soils and in heavy residues where soil penetration might otherwise be an issue. All while still working ultra-shallow and moving substantially less soil than a conventional disc.

- Perfect Fit. Lifetime warranty and optimal bearing protection.

- Milled cutouts maintains shape longer.

- More aggressive on heavy residues such as silage maize, heavy oil seed rape stalks or sunflower stubble.

- Increased penetration capacity in heavy land or hard conditions.

- V-55 steel: Unique working life.

Great ground contour following

CrossCutter Disc is fitted to the versatile disc cultivator Väderstad Carrier. Since each CrossCutter Disc is individually mounted to its own rubber suspended disc arm it has a great ability to follow the ground contour, thus ensuring very even results. You benefit from high precision without compromises.

Less fuel - higher speed

Since CrossCutter Disc work in ultra-shallow working depth at 2-3cm it will move substantially less soil than a conventional disc. This means less fuel used, whilst increasing the working speed. CrossCutter Disc work at its peak level in driving speeds between 15-20km/h.

Point and disc configurator

Väderstad provides points and discs for all needs and conditions. To optimize the working result, it’s important to use the right wear part. Väderstad’s point and disc configurator helps you find the right parts for your machine and conditions.

Swedish steel – Swedish quality

The Väderstad V-55 Swedish steel combines a very high hardness with a preserved shock resistance. Compared to industry standard, the unique Väderstad V-55 pushes the hardness level from standard HRC 47-48 to HRC 55. You benefit from lower wear part costs and less downtime.