Rapid A 400-800S

4-8m

125mm

>130hp

2900-3100litre

Ready for future farming

The pneumatic seed drill Rapid A 400-800S is a powerful drill ready for future farming. The three seed drills in the product family are seed-only versions equipped with a high precision metering system. Rapid A 400-800S is designed with the driver in focus, while never compromising on the important seeding precision and crop quality.

Rapid is a seed drill that carries out seedbed preparation, levelling, drilling and reconsolidation in one pass. It offers a reliable seeding result at high working speed. The simplicity in construction, paired with a high machine quality ensures a long working life and low operating costs. Direct drilling, reduced tillage or conventional tillage – Rapid creates perfect seeding results in all conditions.

Selected features

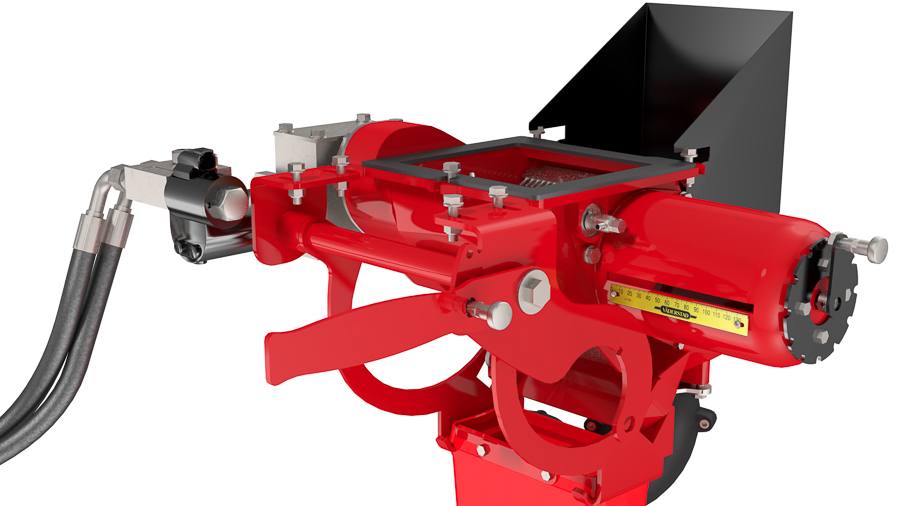

Exact seed metering

At the base of the seed hopper, the seed enters the hydraulic metering system and is distributed pneumatically to the distribution heads.

The metering system Fenix can handle seed rates from 1.5kg/ha up to 500kg/ha without any parts having to be changed. Thanks to the hydraulic drive, high seed rates can be metered without lowering the driving speed.

The integrated fan runs at low speed, resulting in low fuel consumption and quiet operation. Its high location reduces the amount of dust and crop residues that gets in, increasing drilling accuracy.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Full control with Väderstad SeedEye

Väderstad SeedEye is a unique system for seed counting and seed monitoring. With SeedEye farmers can easily set the number of seeds per square metre, without the need for calibration. SeedEye ensures excellent seeding results with full control.

Depth setting from the cab

To be able to instantly adapt to varying soil types or differing conditions in the field, Rapid A 400-800S can be equipped with the unique depth control system Interactive Depth Control (IDC). The system enables fine-tuning of the seeding depth with 1mm accuracy on the move.

Combined with the possibility to alter the seed rate, the driver is constantly in full control of the seeding operation.

By optimising output, the crop get the best start possible, leading to perfect emergence.

Full access

Rapid A 400–800S has a centralised platform with access from both sides, saving time for the operator. Both the hopper and the fan can be accessed when required from the platform.

To minimise downtime in the field, all discs are equipped with maintenance-free bearings.

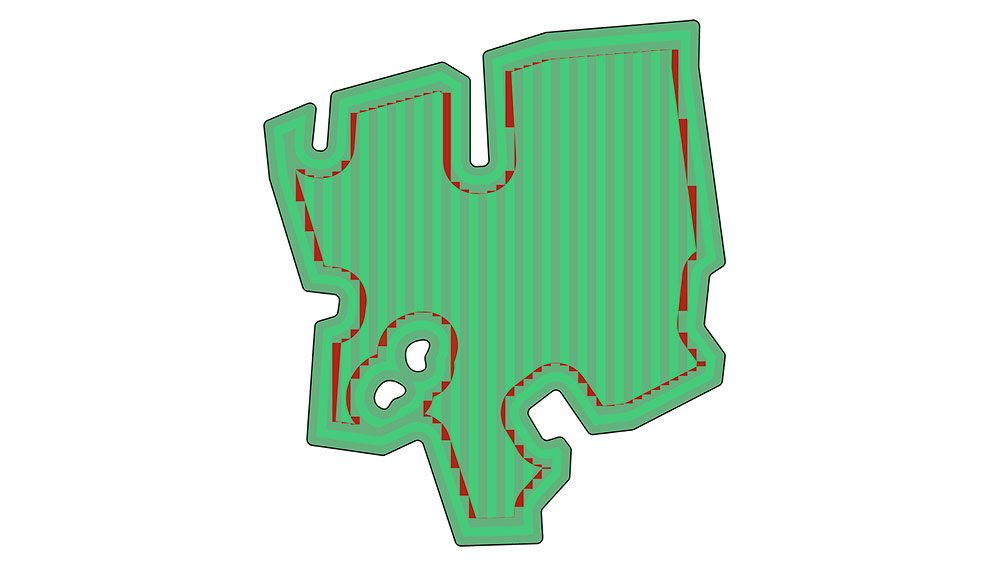

Save money on irregular fields

As standard the wider models Rapid A 600S and Rapid A 800S are equipped with half-machine shut-off. The system is activated from the cab.

Using on irregular fields offers the potential for great savings.

Farmers who regularly use half machine shut-off appreciate the fact that they can save up to 5% seed and fertiliser, whilst at the same time ensuring the crop get the best start possible.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Easy-to-use tramlining

The dynamic tramlining function makes tramlining simpler and more reliable than ever before. The function is easy to setup with the iPad-based control system Väderstad E-Control. When seeding the field, the seed drill automatically shuts off specific rows when needed to match the tire tracks of the sprayer.

Modern control system

The iPad-based control system Väderstad E-Control wirelessly delivers an extensive control and monitoring of the seeding process, while driving on the field. Additionally, you benefit from user-friendly remote set up and calibration

With the iPad you can upload the most recent program software which allows you to benefit from future developments.

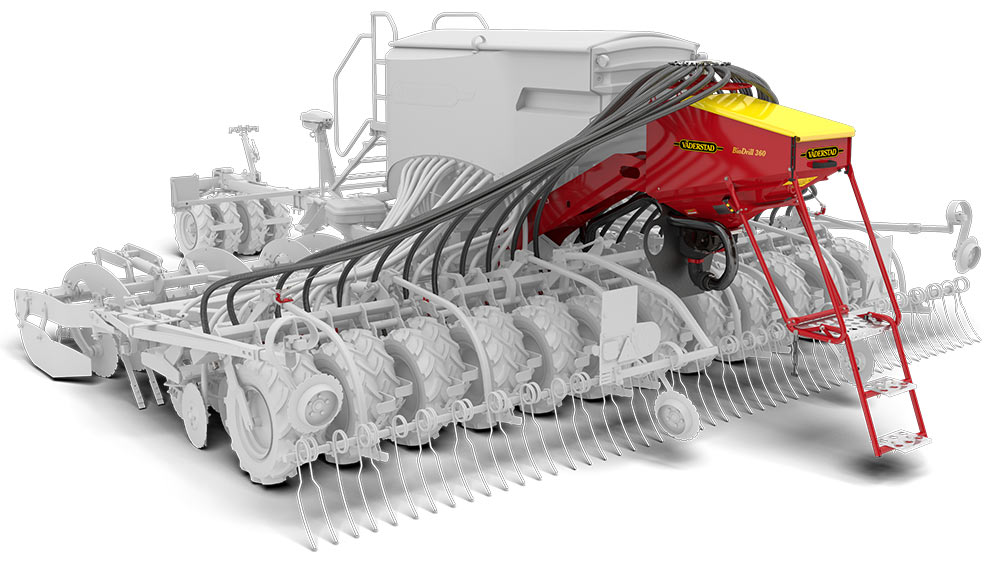

Multiple operations in one pass

By equipping Rapid A 400-800S with the mountable small seeder BioDrill 360, a small seeded crop such as cover crops or ley, can be drilled together with the main crop.

The spreader plates distribute the seed evenly in front of the packer wheels, thereby securing a good seed-to-soil contact.

BioDrill provides an accurate seeding at the same time as saving passes on the field.

QuickStart videos

See our QuickStart movies for your Rapid A 400-800S

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Product concept

Zone 1 - Consolidation

Before drilling, the soil is consolidated by the tractor wheels. The pivot packer on Rapid ensures that the same reconsolidation is exerted on areas between tractor wheels.

Zone 2 - Seedbed preparation

To fit different farming needs and tillage practices, Rapid comes with a wide choice of front tools.The intensity can be set hydraulically from the driving seat on the move, depending on what the conditions require.

Zone 3 - Drilling

Rapid has an amazing ability to keep the seed depth under the most difficult conditions. Each packer wheel controls the drilling depth of two coulters by a unique mechanical linkage. The coulters are rubber suspended which ensures a calm operation also at high speed. Rapid has up to 150kg coulter pressure, which enables penetration also under the toughest conditions.

Zone 4 - Consolidation

Each packer wheel presses the soil down over two rows of seed and one row of fertiliser. This beds the seed in thoroughly and provides optimum conditions for germination.

Zone 5 - Finishing

The following harrow creates a loose evaporation barrier that prevents surface crusting after heavy rain.

Image gallery

Technical data

| Rapid A | 400S | 600S | 800S |

| Metering | Hydraulic | Hydraulic | Hydraulic |

| Working width (m) | 4,0 | 6,0 | 8,0 |

| Transport width (m) | 3,0 | 3,0 | 3,0 |

| Transport height (m) | 3,1 | 3,1 | 4,0 |

| Transport length (m) | 8,0 | 8,0 | 8,0 |

| Basic weight (kg) | 5200 | 6000 | 7700 |

| Volume seed hopper (l) | 2900 | 3100 | 3100 |

| Number of seed coulters | 32 | 48 | 64 |

| Row spacing seed (mm) | 125 | 125 | 125 |

| Number of fertiliser coulters | - | - | - |

| Row spacing fertiliser (mm) | - | - | - |

| Seed coulter pressure min/max (kg) | 117/255 | 110/205 | 88/175 |

| Disc diameter front tool SDA (mm) | 450 | 450 | 450 |

| Seed disc diameter (mm) | 410 | 410 | 410 |

| Wheel dimension (transport wheels) | 190/95x15 | 190/95x15 | 190/95x15 |

| Wheel dimension (support wheels) | - | 190/95x15 | 190/95x15 |

| Hydraulic requirement | 3-4 DA + 1 FR | 3-4 DA + 1 FR | 3-4 DA + 1 FR |

| Draught requirement from (hp) | 130 | 180 | 240 |

| Oil capacity for hydraulic fan (l/min) | 40 | 40 | 40 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic | SDA = System disc aggressive |

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.