Spirit 400-900C

4-9m

125mm

>125hp

5000 litre

Precision and capacity

Spirit 400-900C is a pneumatic seed drill for both seed and fertiliser, available in 4, 6, 8 or 9 metre working widths. The 5000 litre hopper with large opening, result in fewer fills. Both the fertiliser and seed metering have impressive capacity. Spirit 400-900C is equipped with innovative solutions that increases the precision and simplifies the operations at the farm.

The pneumatic seed drill Spirit carries out levelling, seedbed preparation, reconsolidation, seeding and pressing in one pass. It is known to provide impressive precision at high working speeds on the field. Thanks to the individual row depth control, Spirit always places the seed at the intended seeding depth. You benefit from an even emergence over the entire field.

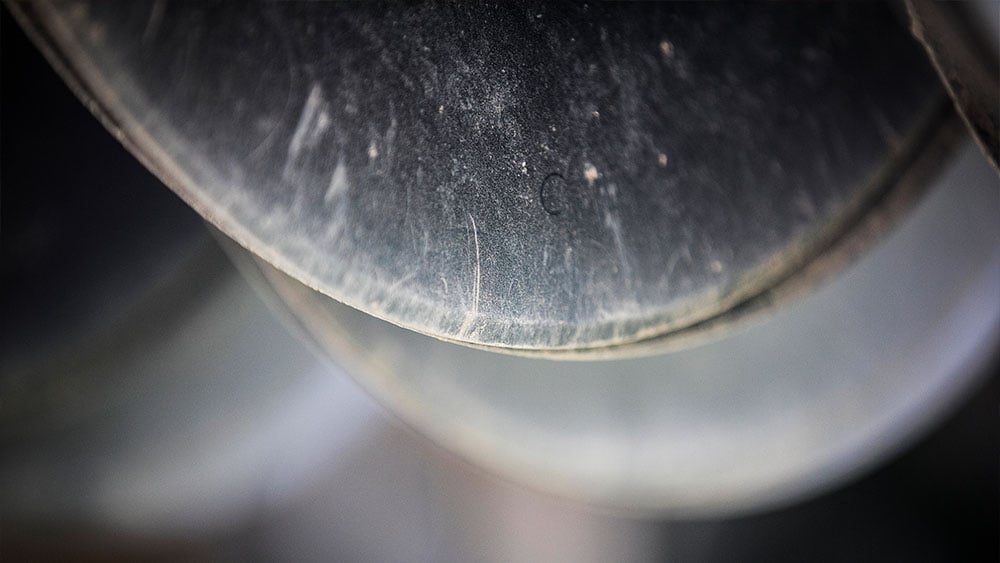

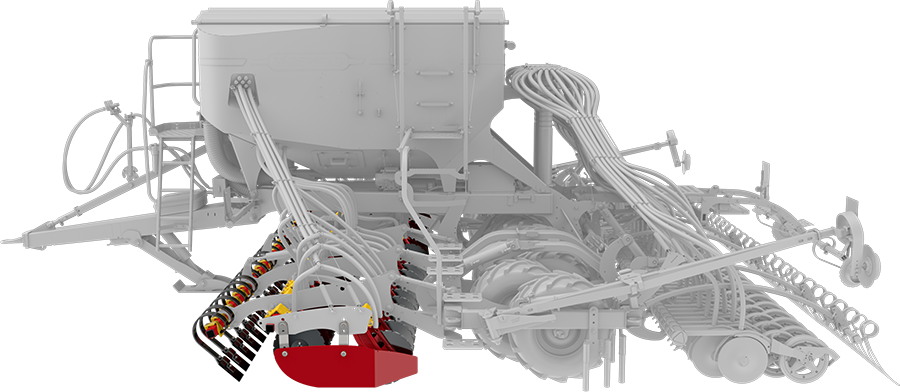

The seed coulter

Perfect seed placement comes down to the details. The Spirit 400-900C coulter design leaves nothing to chance, ensuring that each seed is given the best possible conditions for growth. This helps maximise the potential of every seed in the field.

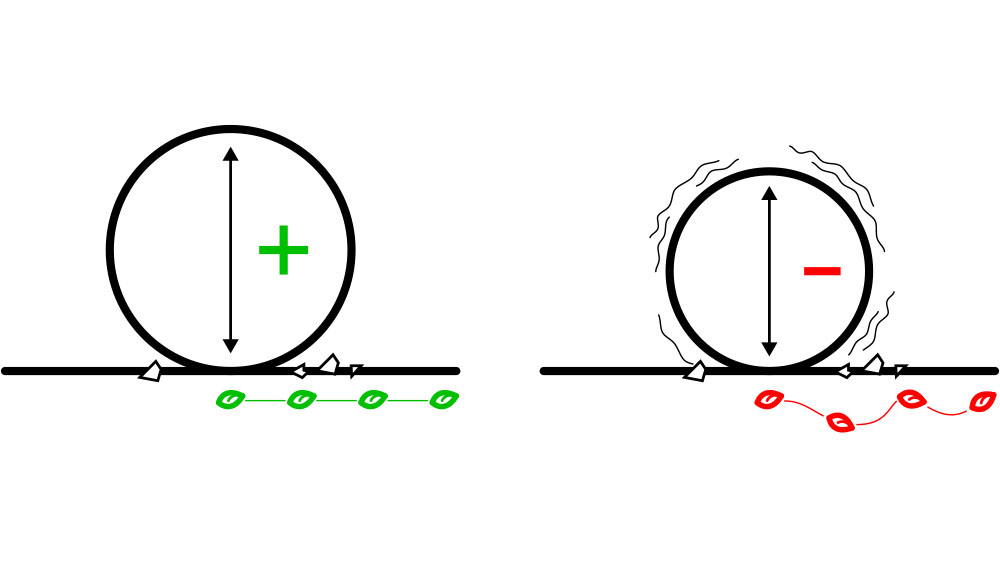

TriForce II® seed coulter suspension

The TriForce II® seed coulter suspension brings greater precision to the field. Thanks to its unique design, the coulter has an unmatched ability to maintain its set pressure, even when challenged by irregularities in the terrain. The result is a more consistent seed depth, leading to even germination and more uniform crop emergence.

Advanced computer modelling shaped the unique triangular beam, enabling the suspension to function like a “lower and higher gear” to deliver optimal pressure at all angles.

Even emergence

Uniform seed depth ensures crops grow evenly, enhancing plant competition and maximising yield potential.

Maximising yield potential

Avoid shallow or deep seed placement, which can lead to poor germination and potential yield loss.

Adapted for each field

TriForce II® is engineered for real-world conditions, recognising that every field is unique.

Extended pressure range

With up to 120 kg of coulter pressure, the seed coulter system expands its operational range. This enables high-performance seeding in light to medium soil conditions without compromising on precision.

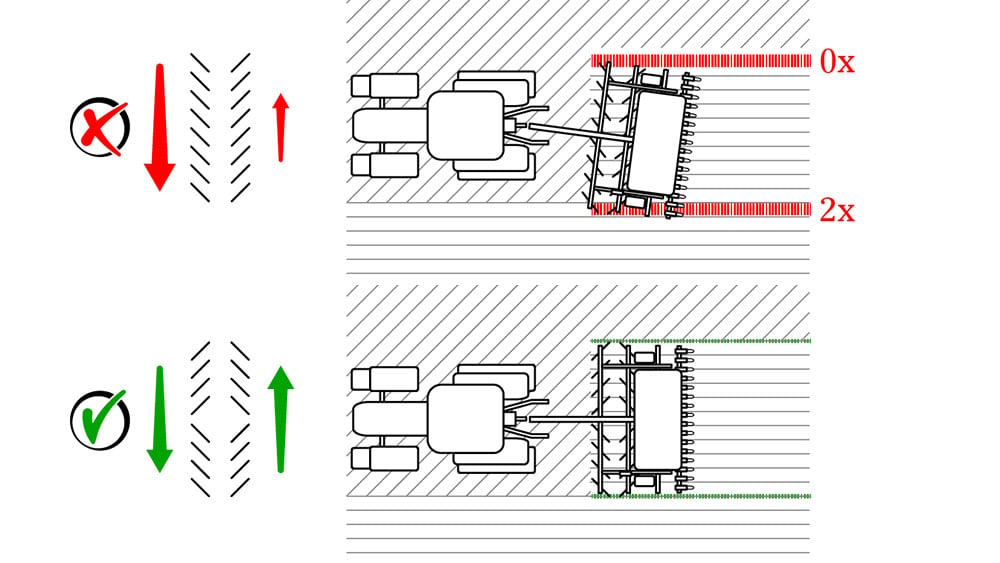

Consistent seed depth

TriForce II® ensures that each individual seed coulter maintains its set pressure, even when the coulter arm is angled upwards or downwards due to field irregularities. This leads to a uniform seed depth, promoting even germination, consistent crop emergence, and improved yield potential.

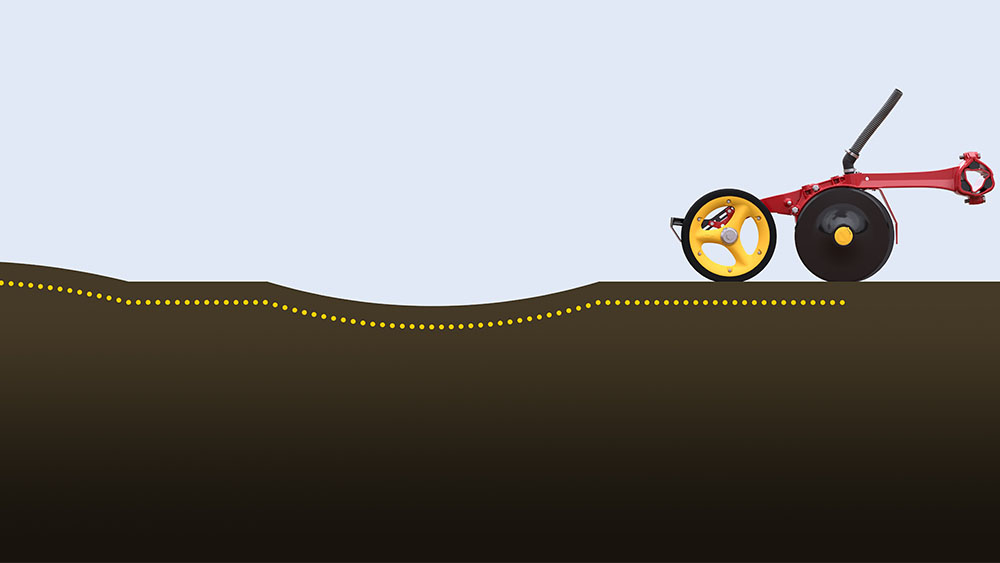

Spirit 400-900C adapts to the field

A seed placed at the correct depth will emerge at the right time, gaining a competitive advantage over pests and weeds. With this in mind, every part of the Spirit seed coulter is engineered for precision, ensuring optimal conditions for strong and even crop establishment.

Uneven ground

Each seed coulter on Spirit 400-900C is mounted on its own arm, allowing it to respond independently to irregularities in the field. This design ensures that the working depth is consistently maintained across the entire working width, even in uneven terrain.

Varying soil types

To adapt to changing soil conditions, coulter pressure can be adjusted from the cab while working. This ensures consistent seed depth across the entire field, even when soil types vary. The wide press wheel helps maintain surface contact, reducing the need for frequent pressure adjustments.

Hilly terrain

To maintain consistent seed depth in hilly terrain, Spirit 400-900C is equipped with active seed coulter pressure. The system instantly detects whether the machine is on a crest or in a trough, and automatic valves adjust the pressure accordingly. This ensures precise seed placement, even on uneven ground.

Smart control from the cab

Hydraulic depth setting and E-Control integration allow operators to monitor and adjust seeding parameters directly from the cab using an iPad. This streamlines setup and boosts operational efficiency, giving you full control on-the-go.

Modern control system

Spirit is equipped with the iPad-based control system Väderstad E-Control.

In addition to an extensive control and monitoring of the seeding process, the control system offers the possibility to adjust the working depth of the front tool, the seed coulters as well as the hydraulic following harrow, while driving on the field.

User-friendliness, cost-effectiveness and an easy to update system are some of the major advantages.

Experience the Spirit 400-900C in action

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Spirit 600-900C

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Spirit 600C InLine

125mm row spacing for maximum yield

Competitiveness

A narrow row spacing gives the crop significantly better competitiveness against weeds—especially important as herbicide-resistant species become more common. Research shows that a 125 mm row spacing results in 20% fewer weeds compared to 150 mm, helping to protect yield and reduce reliance on chemical control.

Population distribution

A 125 mm row spacing improves population distribution by allowing greater spacing between seeds within the row. This not only supports healthier plant development but also helps reduce fungal pressure, contributing to a more resilient crop.

Canopy closure

Narrow rows close more quickly, reducing evaporation at a time when access to moisture is most critical. This helps preserve soil moisture and supports healthy crop development during early growth stages.

Three fertilising methods

Placing fertiliser during drilling provides a fast and reliable fertilisation effect. Since it’s applied directly into moist soil, the crop is less dependent on rainfall, while placement also supports higher yields and improved nutrient use efficiency. To suit different farming needs, the combi-version of Spirit is available with three fertilising methods: FIX, Nordic, and InLine.

FIX

The FIX-version have fertiliser coulters mounted in the front tool, eliminating an additional power requirement. The fertiliser is placed in 5cm wide strips at 125mm row spacing, in front of every seed row. The fertiliser depth can be adjusted from the cab according to the soil condition. The seed benefits from a fast and effective nutrient uptake.

Spirit 400-900C FIX is available in 4, 6, 8 and 9 metre working widths.

Nordic

The Nordic-version has aggressive disc fertiliser coulters that places fertiliser with a very high coulter pressure between the seed rows at 250mm row spacing. A benefit in conventional tillage spring drilling in dry conditions.

Spirit 400-900C Nordic is available in 4, 6, 8 and 9 metre working widths.

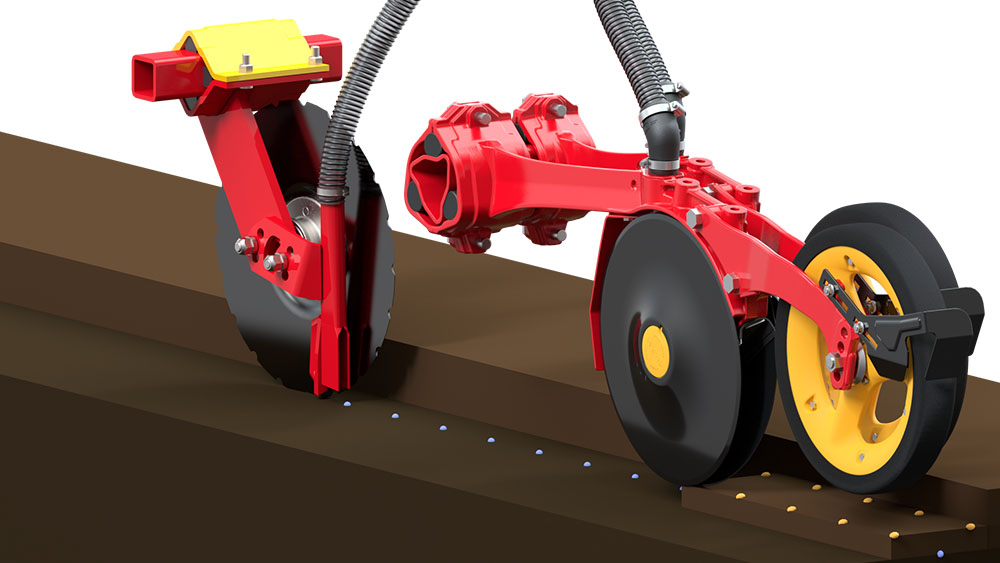

InLine

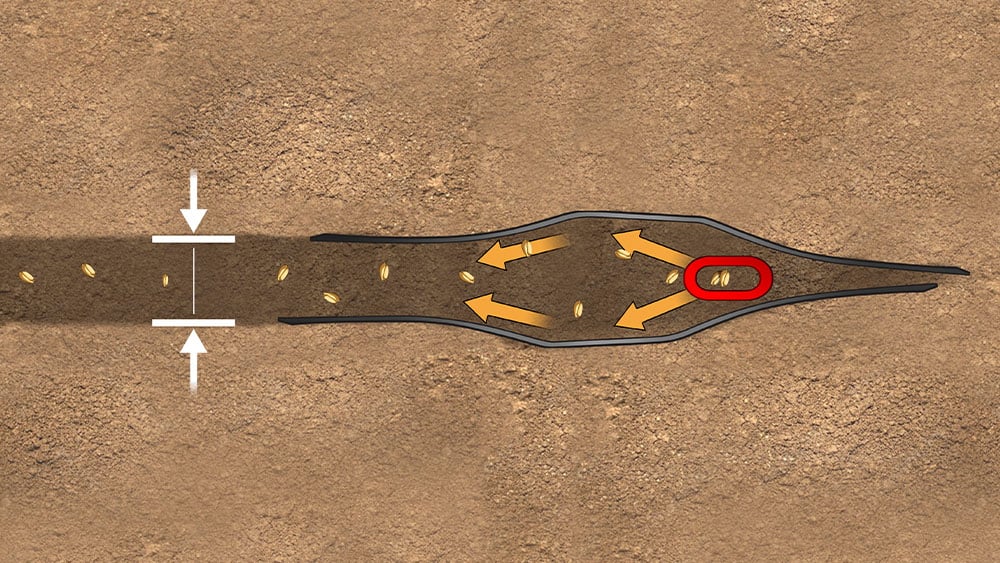

The InLine-version places a low fertiliser rate in a separate outlet together with the seed in the seed coulter, providing the plant quick nutrient uptake. By separating the seed and fertiliser transport, these two distribution systems do not interfere with each other. This enables separate high accuracy blockage monitoring.

InLine is available on Spirit 400-600C, in 4 and 6 metre working widths.

Full-scale seedbed preparation

Spirit 400-900C is equipped with powerful front tools that can be adjusted from the cab while working. For additional levelling, an individually adjustable CrossBoard can be mounted ahead of the disc tool, ensuring a well-prepared seedbed tailored to field conditions. To ensure a firm seedbed before seed placement, large packer wheels consolidate the soil between the front tool and the seed coulters. This provides significant advantages in lighter soils, as well as in fields where the soil is loose due to deep cultivation or insufficient reconsolidation.

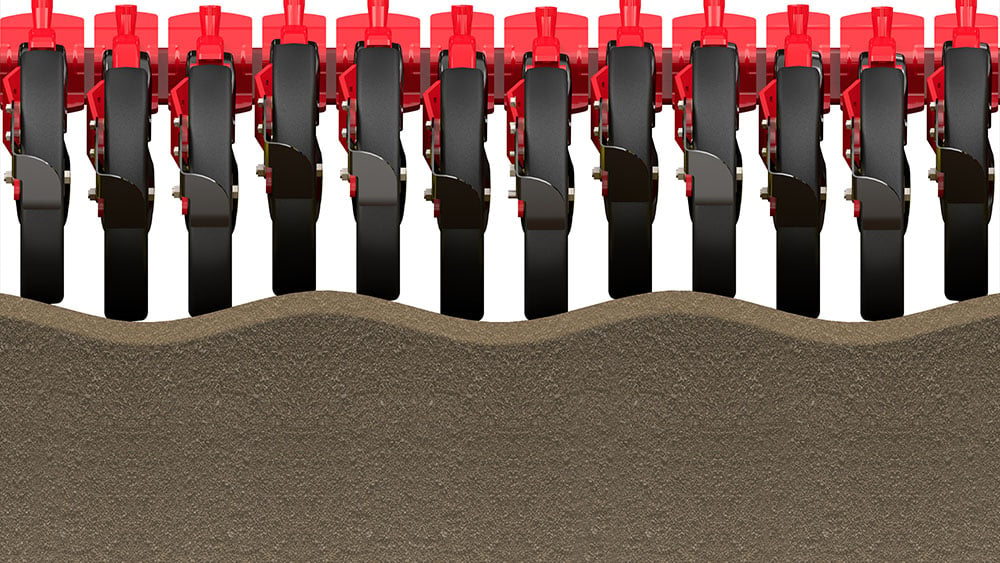

Contour following and high throughflow

Each disc is mounted on an individually suspended arm, ensuring excellent contour following and consistent conditions for every seed. The open design allows high throughflow, making it suitable for drilling in heavy crop residues, while all bearings are well protected at the rear of the disc.

Straight tracking for precision

To maintain a straight track behind the tractor, especially important in hilly terrain, Spirit 400-900C features an X-disc setup in the front tool. This configuration is essential for modern farming and maximises the benefits of GPS and RTK systems.

Stable angle at any depth

Mounted on a parallel linkage, the front tool maintains a consistent working angle regardless of depth. The conical disc shape ensures the same angle is preserved, no matter the level of wear or working depth.

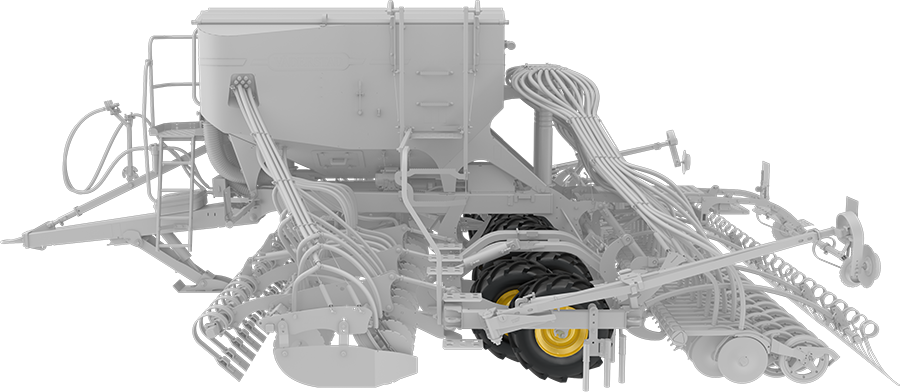

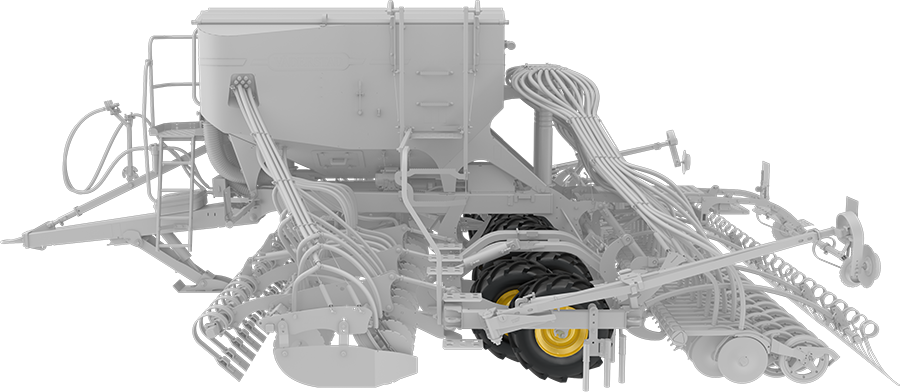

Wheels designed for performance

The large diameter of the packer wheels provides a smooth ride at high speed. Thanks to low rolling resistance and a tread pattern designed to minimise bulldozing, fuel consumption is also reduced. The width of the packer wheels ensures level results across the entire working width.

Each wheel is mounted individually, allowing easy access for maintenance.

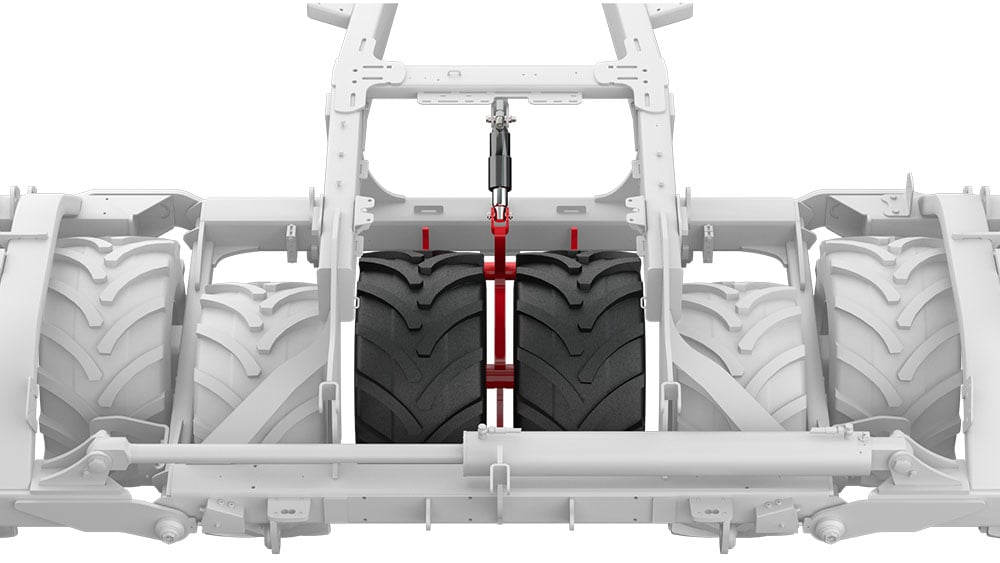

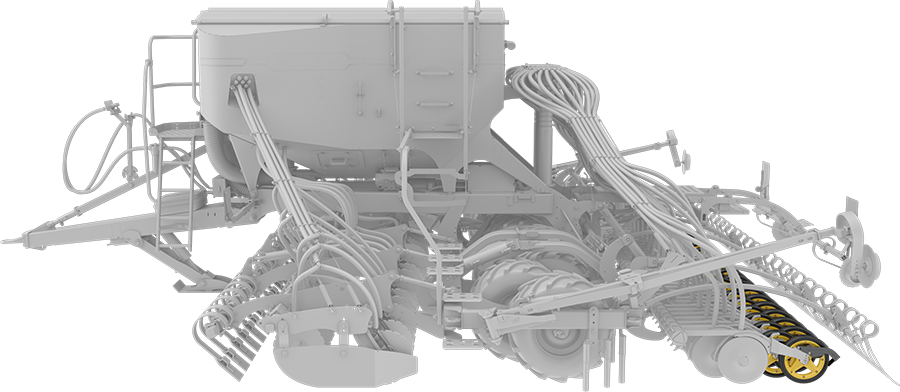

Double-acting middle packer for even emergence

To ensure uniform conditions across the working width, Spirit 400-900C is equipped with a hydraulically adjustable middle packer that runs between the tractor wheels. This supports even crop emergence and also improves stability and safety during transport on uneven roads.

Offset improves agronomy and efficiency

Offset means every second packer wheel is positioned slightly backwards on a separate axle.

- Studies show that offset reduces bulldozing and lowers the draught requirement by up to 25%.

- The large offset wheels provide a smoother ride with reduced vibrations, resulting in more accurate depth control.

- Two separate wheel axles increase the contact surface with the soil, offering greater carrying capacity.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

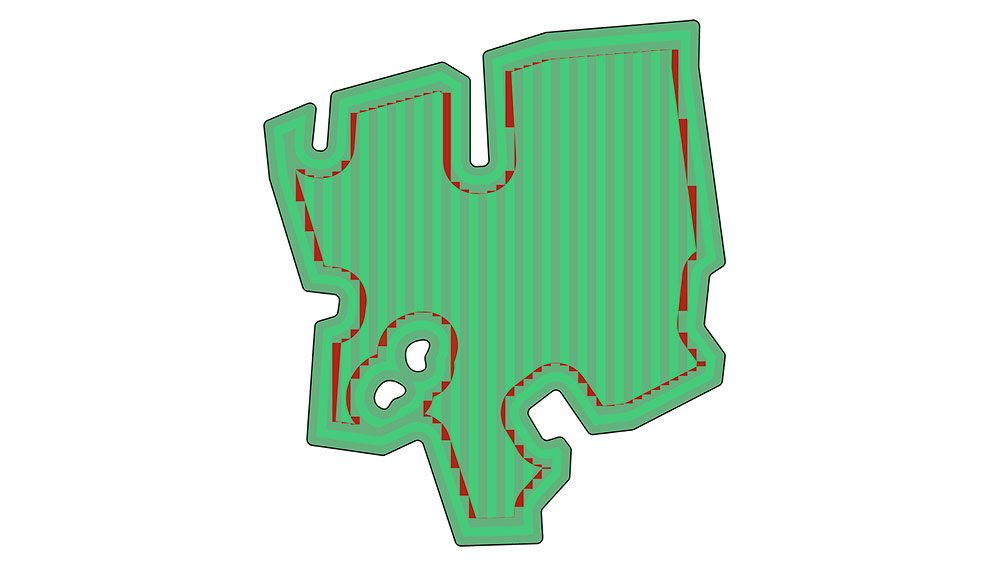

Easy-to-use tramlining

The dynamic tramlining function makes tramlining simpler and more reliable than ever before. The function is easy to setup with the iPad-based control system Väderstad E-Control. When seeding the field, the seed drill automatically shuts off specific rows when needed to match the tyre tracks of the sprayer.

High capacity seed metering

Spirit 400-900C is equipped with two Fenix II metering systems that provides a constant and reliable seed metering. The strong motor permits high seed rates at high speed.

Due to the high location of the integrated fan, the dust intake is minimised, thereby increasing drilling accuracy.

To optimise the air distribution according to the respective seed and fertiliser type, all airflows are adjusted with the integrated AirBalance system.

Fertiliser metering without limits

The fertiliser is metered out via a distributor auger located at the front of the hopper. A hydraulic motor drives the auger and provides limitless fertiliser capacity.

Due to a dividing wall in the hopper, the relation between the seed and fertiliser sections can easily be adjusted. If needed the whole hopper can be used for seed.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Full control with Väderstad SeedEye

Väderstad SeedEye is a unique system for seed counting and seed monitoring. With SeedEye farmers can easily set the number of seeds per square metre, without the need for calibration. SeedEye ensures excellent seeding results with full control.

Save money on irregular fields

To offer the ability to optimise the output on the field, Spirit 400-900C is equipped with half machine shut-off for both the seed and fertiliser which helps avoid double drilling and uneven crops.

On irregular fields, this section shut-off offers great opportunities for extra savings.

Farmers who regularly use half machine shut-off appreciate the fact that they can save up to 5 % seed and fertiliser, at the same time allowing the crop the best start possible.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Automatic headland management

When lifting or lowering the seed drill at the headland, the automatic sequence control lifts or lowers the working zones one by one. When entering the field the system makes sure the front tool is lowered into the soil before the seed coulters and the following harrow.

By optimising this automatic lifting and lowering sequence, the seeding and fertiliser accuracy is enhanced at the headlands.

This system makes it possible to drill the headland first, without disrupting the result when drilling the rest of the field.

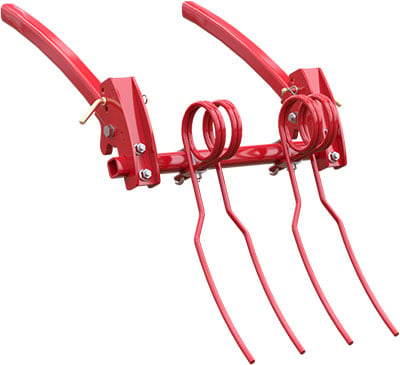

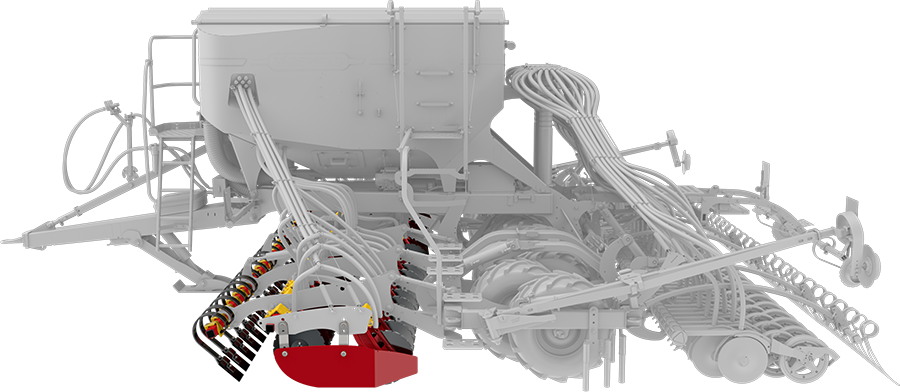

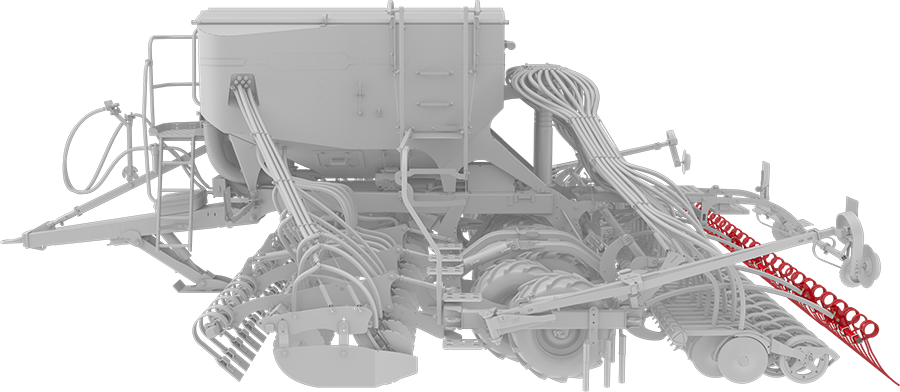

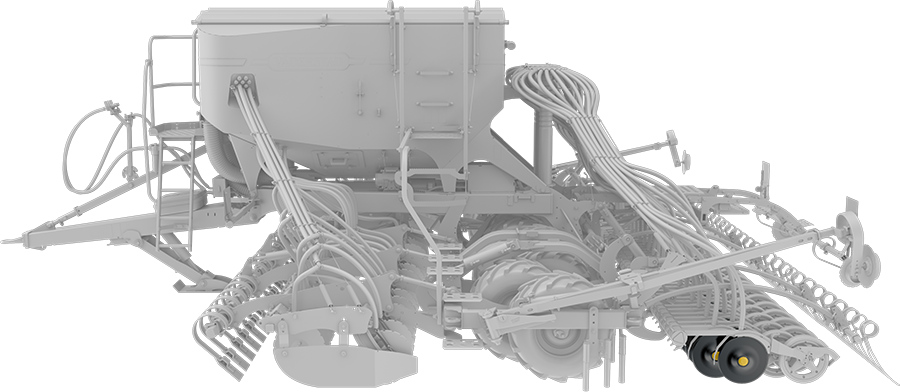

Save passes with BioDrill

By equipping Spirit 400-900C with the mountable small seeder BioDrill, a small seeded crop such as cover crops or ley, can be drilled together with the main crop.

The spreader plate distributes the seed very evenly in front of the following harrow.

An alternative way to use the BioDrill is for slug pellets, which are distributed through nozzles positioned behind the following harrow heavy. Slug pellet and seeder nozzles can be combined.

BioDrill provides an accurate seeding at the same time as saving passes on the field.

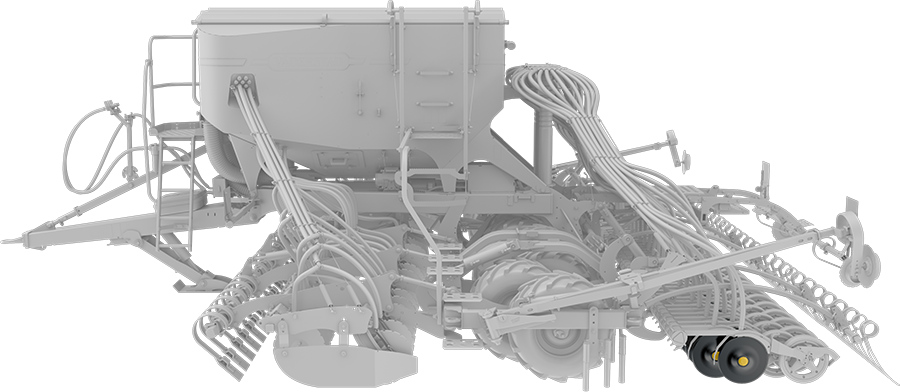

Product concept

Zone 1 - Seedbed preparation

Spirit 400-900C can be adapted to fit different farming needs. It is available with different techniques for placing fertiliser with the front tools. The working depth of the front tools can be easily adjusted from the tractor cab.

Zone 2 - Consolidation

To ensure a firm seedbed prior to seed placement, large packer wheels consolidates the soil between the front tool and seed coulters. This offers great advantages in lighter soil, as well as in fields where the soil is loose as an effect of a deep cultivation or a cultivation with insufficient reconsolidation.

Zone 3 - Seed placement

Spirit has 380mm large discs for high speed accuracy. The OffSet discs move the soil to the side and place the seed in the bottom of the seed furrow. The soil falls back behind the discs and covers the seed with fine soil. The seed coulter pressure is up to 120kg to ensure a good penetration. The unique TriForce II® rubber suspension gives a supreme ability to follow ground contour.

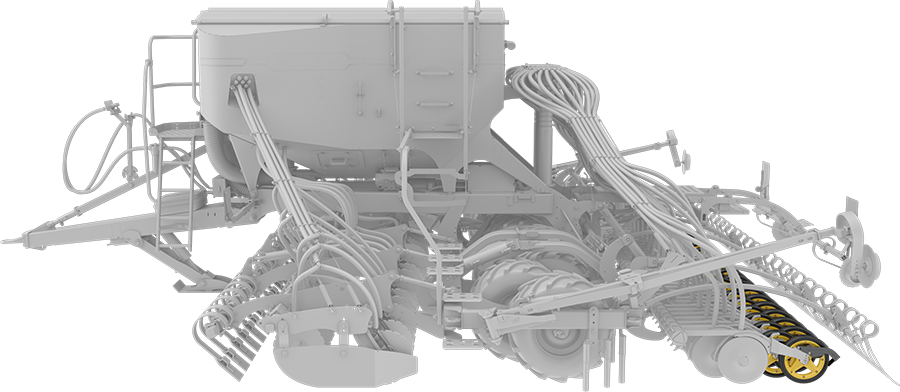

Zone 4 - Reconsolidation

Each individual seed coulter has a wide coulter press wheel. This allows the seed coulters to respond to any irregularities or soil variations on the field, thereby ensuring the working depth is constantly maintained. The generous diameter of the coulter press wheel, further results in a smooth ride with minimal impacts from vibrations, thereby increasing precision at high speed.

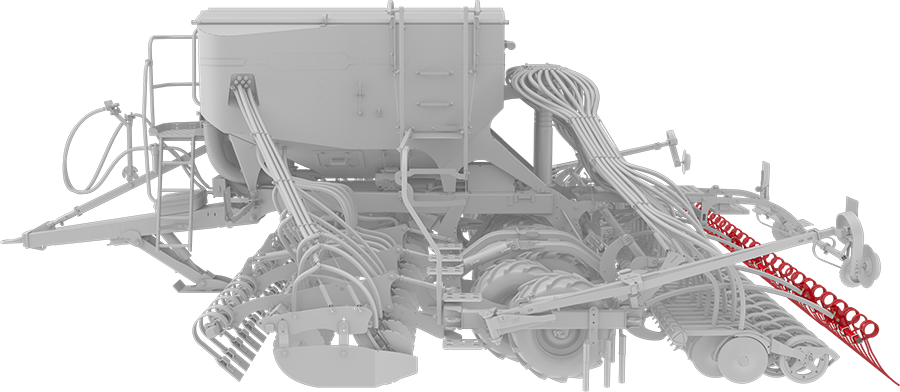

Zone 5 - Finishing

The following harrow is positioned to run in-between the seed rows, so there is no risk of disturbing shallow-drilled seeds. The following harrow creates a loose evaporation barrier to preserve moisture and prevents capping after heavy rain.

Image gallery

Technical data

| Spirit | 400C FIX | 400C Nordic | 400C InLine | 600C FIX | 600C Nordic |

| Metering | Electric | Electric | Electric | Electric | Electric |

| Working width | 4,0 | 4,0 | 4,0 | 6,0 | 6,0 |

| Transport width (m) | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 |

| Transport height (m) | 3,6 | 3,6 | 3,6 | 3,56 | 3,56 |

| Transport length (m) | 8,7 | 8,7 | 8,7 | 8,7 | 8,7 |

| Basic weight (kg) | 5300 | 5300 | 5300 | 7600 | 7300 |

| Volume seed hopper (l) | 5000 | 5000 | 5000 | 5000 | 5000 |

| Number of seed coulters* | 32 | 32 | 32 | 48 | 48 |

| Row spacing seed (mm) | 125 | 125 | 125 | 125 | 125 |

| Number of fertiliser coulters | 32 | 16 | 32 | 48 | 24 |

| Row spacing fertiliser (mm) | 125 | 250 | 125 | 125 | 250 |

| Seed coulter pressure max (kg) | 120 | 120 | 120 | 120 | 120 |

| Seed disc diameter (mm) | 380 | 380 | 380 | 380 | 380 |

| Brakes | H/P | H/P | H/P | H/P | H/P |

| Recommended working speed (km/h) | 8-14 | 8 14 | 8-14 | 8-14 | 8-14 |

| Wheel dimension (transport wheels) | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 |

| Hydraulic requirement | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR |

| Draught requirement from (hp) | 140 | 125 | 125 | 200 | 170 |

| Oil flow requirement (l/min) | 100 | 100 | 100 | 115 | 115 |

| Spirit | 600C InLine | 800C FIX | 800C Nordic | 900C FIX | 900C Nordic |

| Metering | Electric | Electric | Electric | Electric | Electric |

| Working width (m) | 6,0 | 8,0 | 8,0 | 9,0 | 9,0 |

| Transport width (m) | 3,0 | 3,0 | 3,0 | 3,0 | 3,0 |

| Transport height (m) | 3,56 | 3,85 | 3,85 | 4,0 | 4,0 |

| Transport length (m) | 8,7 | 8,7 | 8,7 | 8,7 | 8,7 |

| Basic weight (kg) | 7300 | 10160 | 9140 | 10860 | 10900 |

| Volume seed hopper (l) | 5000 | 5000 | 5000 | 5000 | 5000 |

| Number of seed coulters | 36 | 64 | 64 | 72 | 72 |

| Row spacing seed (mm) | 167 | 125 | 125 | 125 | 125 |

| Number of fertiliser coulters | 36 | 64 | 32 | 72 | 36 |

| Row spacing fertiliser (mm) | 167 | 125 | 250 | 125 | 250 |

| Seed coulter pressure max (kg) | 120 | 120 | 120 | 120 | 120 |

| Seed disc diameter (mm) | 380 | 380 | 380 | 380 | 380 |

| Brakes | H/P | H/P | H/P | H/P | H/P |

| Recommended working speed (km/h) | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 |

| Wheel dimension (transport wheels) | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 | 400/55x15,5 |

| Hydraulic requirement | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR | 4 DA + FR |

| Draught requirement from (hp) | 170 | 270 | 220 | 290 | 240 |

| Oil flow requirement (l/min) | 110 | 130 | 130 | 130 | 130 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| LS = Load sensing | FR = Free return | DA = Double acting | ||

| H = Hydraulic | P = Pneumatic |

* Depending on row spacing - 167/125mm

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.