Marathon 15/25mm point

Working depth: 0-10cm

Point width: 15/25mm

Function: Harrowing

Fits the following machines: NZ Mounted, NZ Aggressive, NZ Extreme

The Väderstad Marathon points are reinforced with tungsten carbide. They ensure a consistent work result, leading to the optimal conditions for crop establishment, maximising the yield potential. With an even soil structure, root development is given the best conditions to access nutrients and water.

Väderstad’s Marathon points are reinforced with tungsten carbide hard metal, providing up to ten times the durability of standard points. Designed for consistent performance and superior stone resistance, they minimise wear and maximise time in the field. Marathon points ensure efficient operation for both deep cultivation and seedbed preparation.

Working depth: 0-10cm

Point width: 15/25mm

Function: Harrowing

Fits the following machines: NZ Mounted, NZ Aggressive, NZ Extreme

Working depth: 0-10cm

Point width: 25/35mm

Function: Harrowing

Fits the following machines: NZ Mounted, NZ Aggressive, NZ Extreme

Working depth: 10cm

Point width: 45mm

Function: Harrowing

Fits the following machines: Rexius Twin

Working depth: 15-30cm

Point width: 50mm

Function: Mixing

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, TopDown

Working depth: 10-30cm

Point width: 50/80mm

Function: Mixing

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, TopDown

Working depth: 10-25cm

Point width: 80mm

Function: Mixing

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, TopDown

Working depth: 20-40cm

Point width: 58mm

Function: Breaking

Fits the following machines: Opus, TopDown

Working depth: 0-5cm

Point width: 300mm

Function: Cutting

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, TopDown

Locate your nearest dealer to purchase machines, spare parts, wear parts, and accessories.

Browse our Parts Catalogue for more parts, detailed information, compatibility, and recommended retail prices.

The Marathon Edge-series of the Marathon points are characterised by their thinner body. This improves the soil searching ability which positively impacts the depth keeping in difficult conditions. Therefore, they are the first choice on vibrating tines such as Väderstad Swift. Marathon Edge offers approximately 4 times the working life of a standard point.

Working depth: 10-30cm

Point width: 50/80mm

Function: Mixing

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, Swift, TopDown

Working depth: 10-25cm

Point width: 80mm

Function: Mixing

Fits the following machines: Cultus 300-400, Cultus HD 300-400, Cultus 425-525, Cultus HD 425-525, Opus, Swift, TopDown

Specifically designed for Väderstad machines, our parts guarantee a perfect fit and excellent agronomic properties.

Väderstad wear parts are engineered to withstand the rigours of farming, delivering outstanding performance and longevity.

Experience the difference in quality and economy with Väderstad's commitment to excellence in every detail.

Our high-quality, durable wear parts ensure optimal equipment performance, reducing overall costs.

Väderstad Marathon points are equipped with a tungsten carbide tip, allowing them to maintain the same working depth and width throughout their long service life.

When paired with the Väderstad MixIn shin, this extended durability ensures consistent and thorough soil mixing from start to finish. The combination delivers reliable results season after season, thanks to the Marathon point’s long-lasting performance.

Thanks to the durability of the Marathon point, you spend less time in the workshop, and no points need to be changed during the season. This means you can spend more time in the field when conditions are at their best. This becomes even more important in tough seasons with especially short windows of opportunity.

Marathon helps save fuel by maintaining a sharp point that moves easily through different soil conditions, always preserving the optimal soil-breaking angle. In contrast, uneven or worn points cause unnecessary soil flow, which leads to increased fuel consumption.

All Marathon points feature a perfectly flat surface, similar to the body of a plough. This optimises soil flow while minimising resistance and reducing diesel consumption.

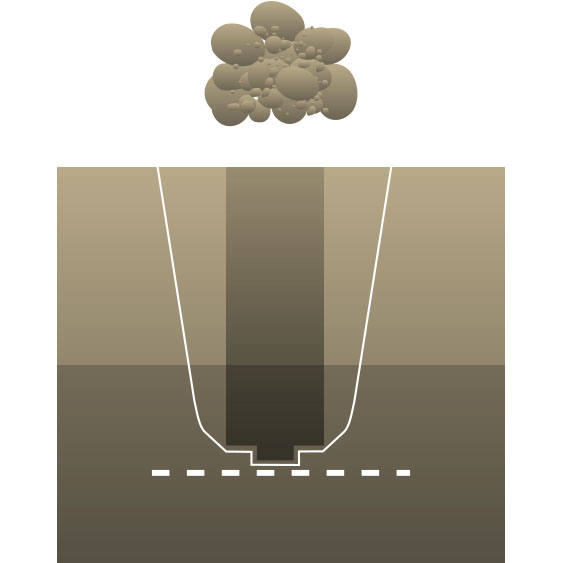

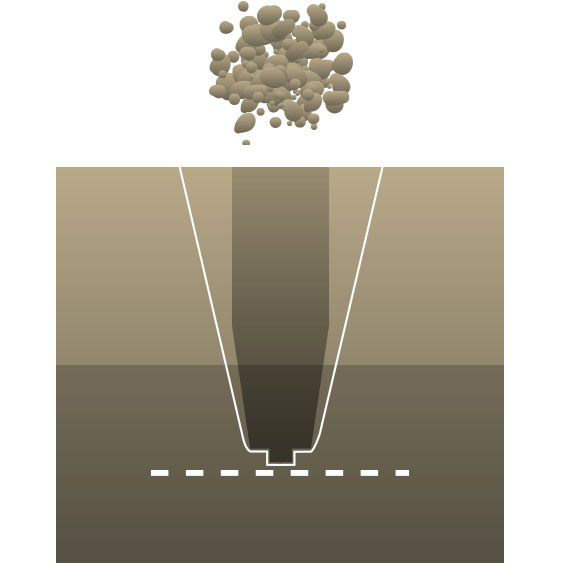

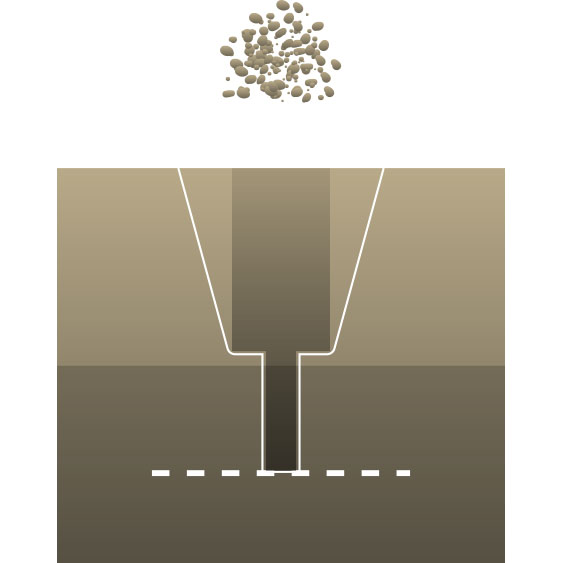

Selecting the correct point depends on the specific tillage task at hand. There are three main objectives that a point can achieve: mixing, breaking, and drainage. Often, the desired result is a combination of these effects or is more closely aligned with two of these targets.

To achieve good mixing, the amount of soil brought to the surface is key. It affects how much crop residue can be mixed in and how deep it goes. The idea is simple: closer row spacing and wider points move more soil. On the other hand, thinner points help improve flow through the machine and reduce power needs when working deeper in the ground.

Combine a straight point with a shin the same width.

Combine a straight point with a widening shin.

Combine a pointed point with a widening shin.

Combine a BreakMix point with a widening shin.

The Marathon Edge 50/80mm offers a sharper point than the Marathon Edge 80mm and can therefore work deeper with maintained draw force requirement. It will enter better in tough conditions. In heavier soils the thinner point bottom lowers the amount of clods created compared to the 80mm point.

A spring tine does an optimal job if it vibrates just at a perfect frequency, the Swift tine has app. 100 vibrations per second. This helps reducing draw force requirement, point wear but also makes it crumble the soil better. A too heavy point would have difficulties coming back to the set working depth in tough conditions and would reduce the small vibrations thus producing less fine tilth.

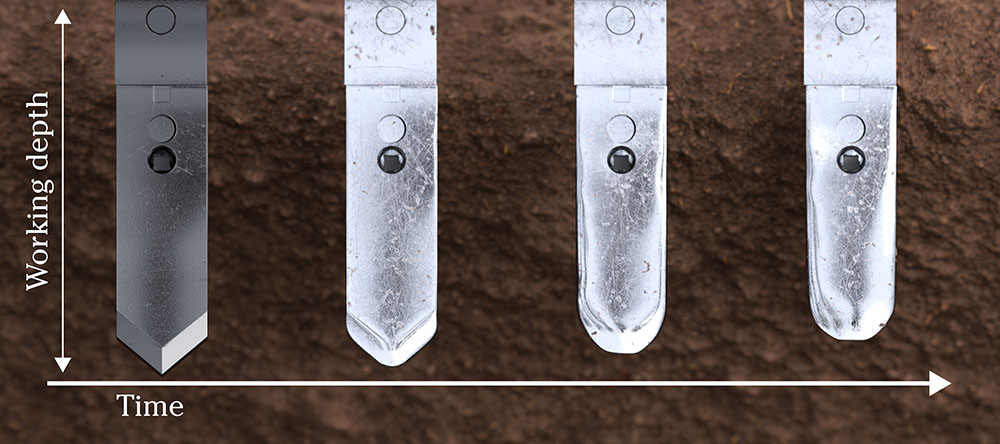

A cultivator will have a higher wear on the points in the front rows and especially in the wheel tracks, this cause an uneven work result. Marathon Edge will keep the working depth throughout its entire life time, delivering a perfect cultivation result. An additional benefit is the work time saved changing the points.

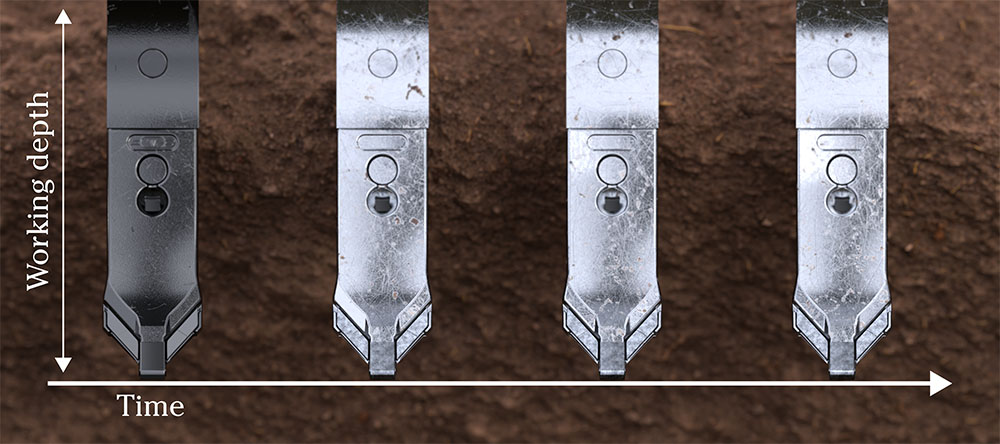

Wear changes working depth.

Depth consistent over time no matter wear.

The Väderstad MixIn shin revolutionises soil mixing by directing soil and residue forwards instead of upwards, enhancing both depth and lengthwise distribution. This unique design doubles the mixing effect, reduces fuel consumption, and creates a finer tilth for improved crop performance.

Discover the Following Harrow Marathon tines, reinforced for longer life and better seedbed preparation. Compatible with various Väderstad machinery, they ensure consistent performance and maximise productive time.

Stay equipped with Väderstad’s digital tools and resources. Read Optimized Performance for articles, news, and maintenance tips. Use the Point & Disc Configurator to find the right parts for your machine. Browse the Parts Catalogue for spare parts and accessories. Explore the Accessories brochure for ideas to enhance your equipment further.

Explore Väderstad’s range of points and discs to suit all conditions. Use our Point & Disc Configurator to easily find the best parts for your machine, tailored to soil type, working depth, and more.

Stay informed with Optimized Performance, our digital magazine for Väderstad farmers. Access valuable articles, news, recommended retail prices for wear parts and accessories, and essential maintenance tips.

Explore our comprehensive online Parts Catalogue for spare parts, accessories, and recommended retail prices to keep your Väderstad equipment running smoothly.

Discover our range of accessories designed to optimise the performance, versatility, and efficiency of your Väderstad agricultural machines. Tailor your equipment to meet your specific farming needs with innovative, high-quality solutions.