Maximize the potential of your crops

Discover unmatched precision and capacity with the Väderstad Tempo Planter, designed for farmers seeking to enhance their yield potential. Tempo delivers excellent planting precision at speeds of 10-12 mph, setting a new standard in field efficiency.

“One of the things that first caught my attention on Tempo was the row unit itself. It is really well-built, and the meter is nice and simple. I like to have just that tube deliver the seed with an airstream and not having extra belts or extra electric motors on it.“

Bryan Biegler, Lake Wilson, MN.

Speed with precision

Break free from conventional limits! The Väderstad Tempo Planter allows you to plant at speeds of 10-12 mph without compromising precision. Cover more ground in less time, unlocking new levels of efficiency.

Unmatched planting precision

Maximize the potential of your crops. The Tempo planter delivers exact seed spacing, even seed depth, and no overlap planting on headlands. Furthermore, the planting precision remains consistent regardless of external influences such as speed, vibrations, slopes, or varying field conditions.

Advanced, yet simple

Enjoy straightforward functionality. The Väderstad Tempo's simplicity of design means no belts, motors, or brushes — just ease of use that allows you to focus on what matters most: growing your crops.

Next-level technology

It’s not just about performance; it’s about the future of farming. The Väderstad Tempo combines cutting-edge technology with practical efficiency, setting a new benchmark for planting excellence.

The Tempo row unit

Every component on the Tempo planter is built to ensure the exact same start for all seeds, regardless of speed or field condition. Consistent seed placement results in a crop that matures evenly and is more likely to yield to its full potential.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

The Tempo seed meter uses positive air pressure to ensure each single seed finds its place on the rotating seed discs, one by one. When the seed reaches the seed tube, the air pressure is cut off to accurately guide the seed into the tube.

Now, the air pressure once again takes control and shoots the seed down to the soil. Since all seeds are granted the exact same transport time from the seed meter down to the seed furrow, precision is ensured. At Väderstad, we call this PowerShoot technology.

One machine - Multiple crops

Corn, soybeans, sugarbeets, sunflowers, canola, cotton, sorghum and many more – the Tempo is capable of planting a full range of crops with excellent results. By easily changing the row spacing and machine setup for different crops, the Tempo offers superior versatility on the farm. The result is increased efficiency and minimized machine costs per acre. Changing the seed discs can be done in a matter of seconds without the need for tools.

Optimal seed-to-soil contact

When the seed leaves the seed tube, it is stopped by the press wheel. The press wheel fulfils two important tasks: it stops the seed at the exact intended spot and then presses it into moist soil. This ensures optimal seed-to-soil contact and fast, even germination.

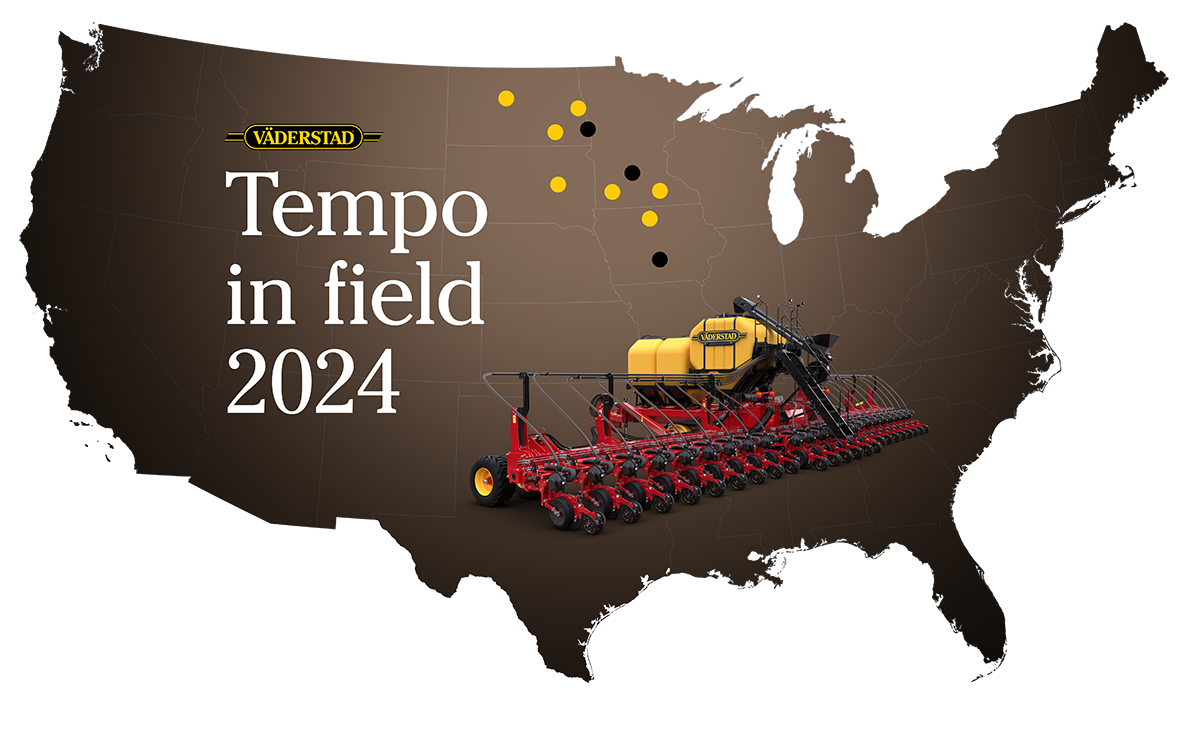

Follow the Tempo planting 2024

This year, the Tempo planter is making its way through the Midwest. Throughout the season, we will have multiple machines in the field, share field- and crop updates, meet farmers, and invite you to join us at field days and tradeshows.

With the help of our field demo team, we welcome you to follow the journey firsthand.

Field testing in America

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Farmers' experiences with Tempo

“With Tempo, I have noticed a lot less doubles and skips out in the field. My spacing has been a lot more consistent and just the evenness going through the field - I can tell that we had a good depth consistency. It has been consistency on the ears, spacing and everything has been looking fantastic this year!”

Bryan Biegler, Lake Wilson, MN.

Join the Tempo Team – Elevate Your Planting Experience!

The Väderstad Tempo Planter is not just a planter; it’s a game-changer for North American farmers who demand more from their equipment. Unleash the power of speed, precision, and efficiency—choose Väderstad Tempo and watch your farmland achieve its full potential.

Sign up for Tempo updates

* indicates required