Tempo L 8-32 Central Fill

8-32

15, 20, 22, 30 in

>150hp

85 bu

Capacity and precision maximized

The Tempo L Central Fill is available with 8, 10, 12, 16, 18, 24 or 32 row units. It is equipped with a high-capacity central seed hopper, which distributes seed to the row units. The Tempo L Central Fill delivers unmatched planting capacity and precision. Plus, it handles a wide variety of seeds - from small seeds like canola, to corn and high rates of soybeans.

The Väderstad Tempo is a new generation high-speed planter, delivering unmatched precision at double the speed of traditional planters. No-till, min-till or conventional tillage – the Tempo performs exceptionally well in all conditions. It gives your crop the best start possible with even emergence.

High-precision seed metering

The technology behind the new Väderstad Tempo Central Seed Fill system is very practical. There is no central motor metering out seeds - Instead, each row unit regulates the number of seeds needed for its high-precision PowerShoot seed metering system.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

High-capacity hopper

Underneath the central 85-bushel seed hopper, there is a feeding system for the row units. An airstream picks up seeds from the gates and sends them out to the row units. Each gate supports two row units through a divider on the wings.

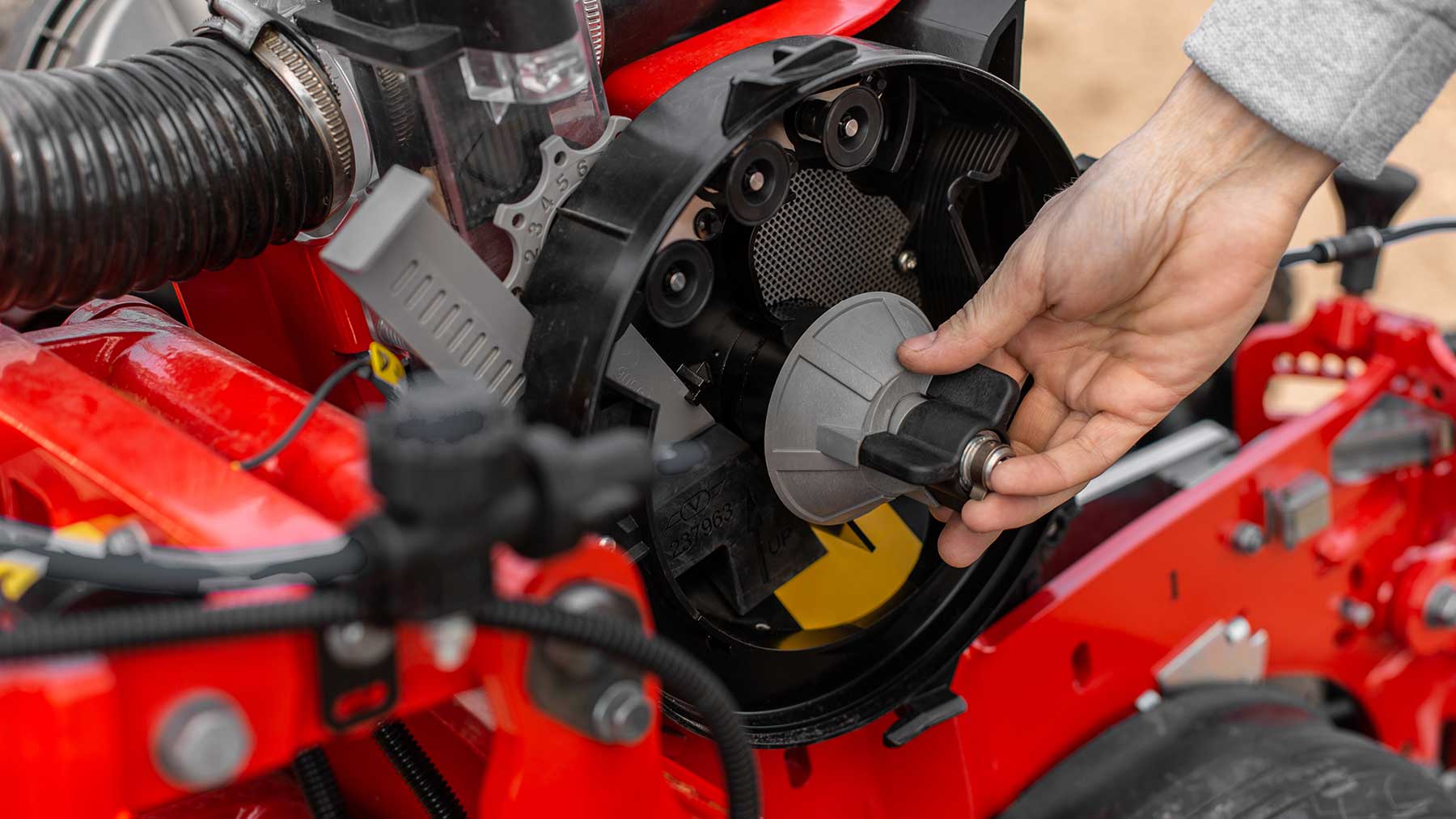

Seed collector

Each row unit has a collector on top of the PowerShoot seed metering system to supply seed for that row. When the collector is full of seed, the airstream from the feeding system stops, pausing the transport of seed to that row unit.

Restarting Seed Flow

When the seed level in a collector starts to run low, the row unit will send a signal to restart the airstream. This allows the Central Seed Fill system to transport more seeds to fill up the collector.

Fertilizer

The Tempo L Central Fill 16 and 24 can be equipped for seed and fertilizer metering. Granular fertilizer is metered through the high-capacity Fenix III metering system, which is capable of rates up to 300 pounds per acre at 10 mph.

Seed-only models are equipped with a central 85-bushel seed hopper, while the seed and fertilizer models utilize a 204-bushel hopper with two compartments: 62 bushels for seed, and 142 bushels for granular fertilizer.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

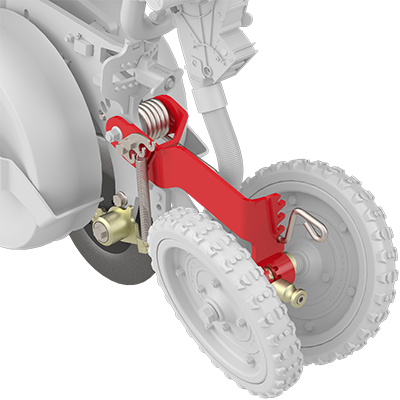

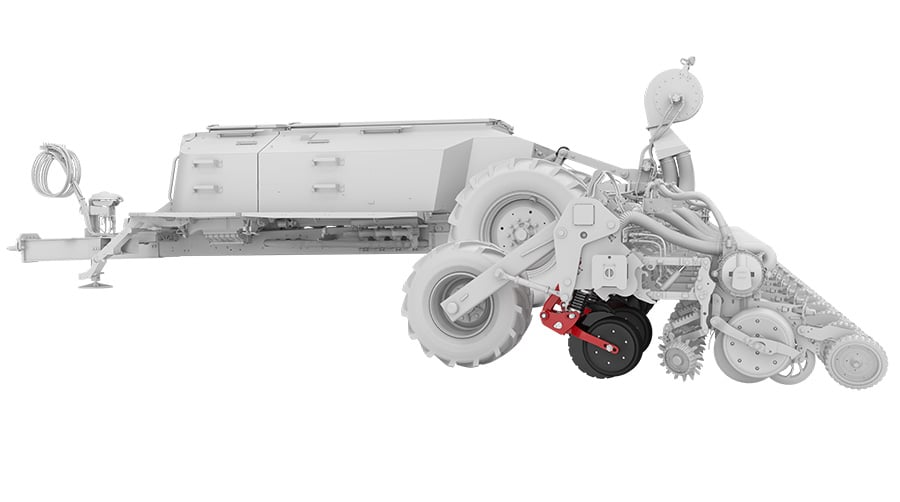

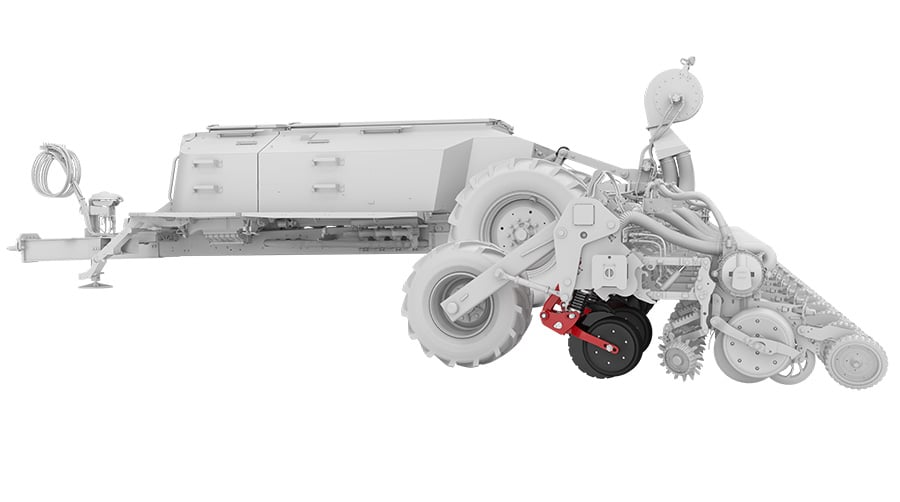

Telescoping wheel axle

To ensure the transport wheels follow the row spacing, the Tempo L is equipped with a telescoping wheel axle, which can be easily adjusted from the cab. So whatever the row spacing, the transport wheels can be adjusted to always run between the seed rows. The wheel axles are easily set to a 10-foot width for transport.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

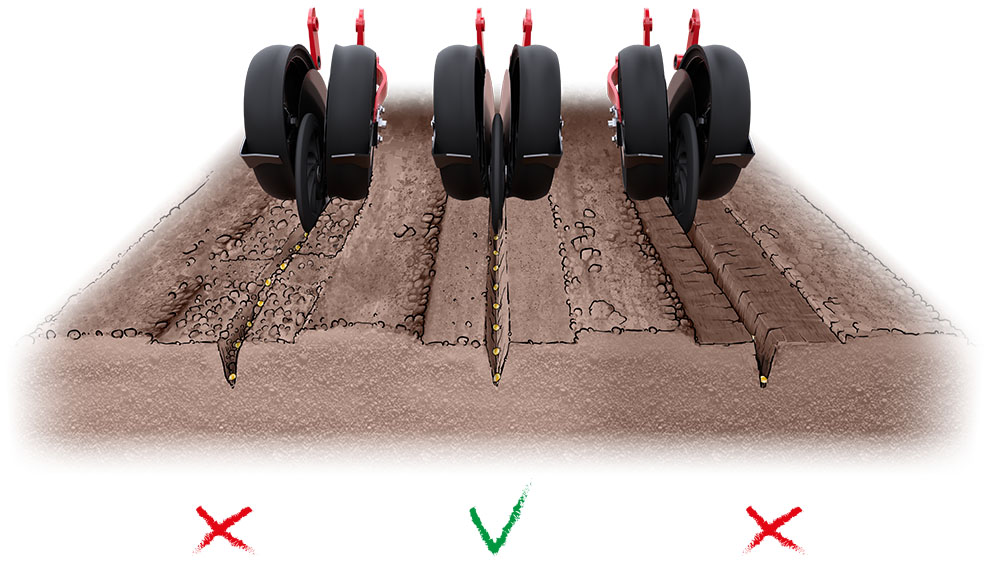

Perfect depth control

The Tempo L is equipped with hydraulic wing pressure, which transfers weight from the inner section of the planter to the outer wings.

This allows the Tempo L to respond to any irregularities in the field and ensure even emergence.

Optimized accuracy with next-level automation

By upgrading the data processing capabilities of the planter, additional features to ensure accuracy in the field are unlocked. The optional features are curve compensation, active hydraulic downforce and auto singulation.

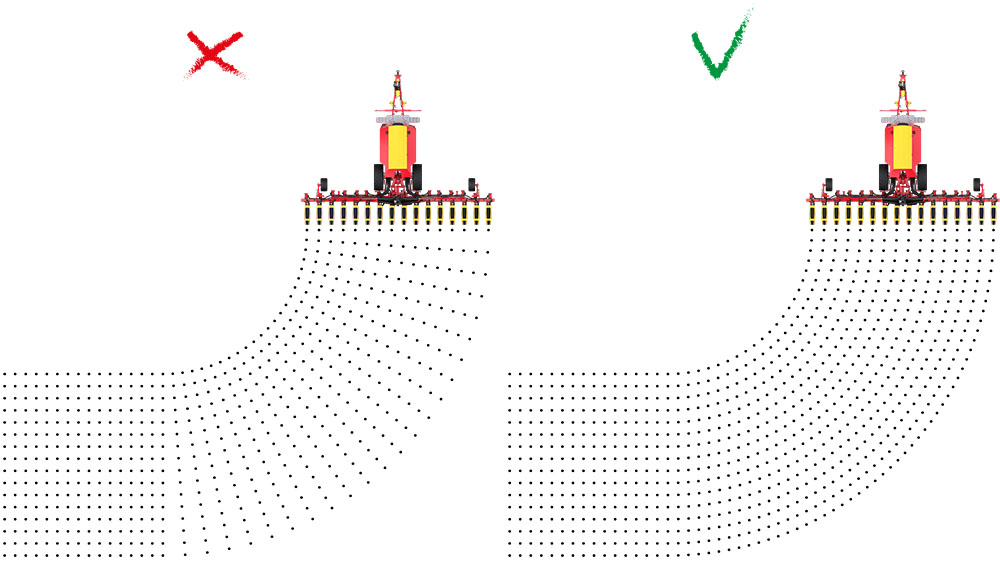

Curve compensation ensures a consistent rate

Active sensors communicate when the machine is turning and adjust the metering output of each row unit to always ensure a consistent rate over the full Tempo planter width.

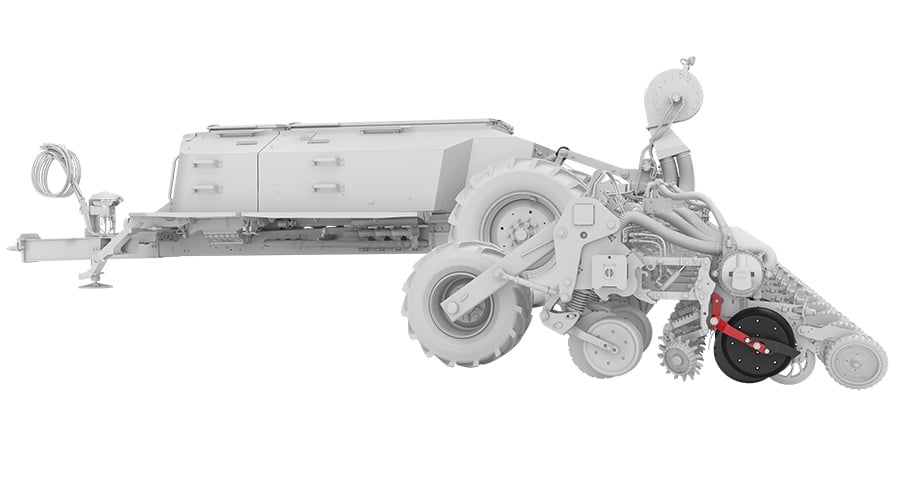

Active hydraulic downforce enables furrow management

With the active hydraulic downforce system, Tempo instantly reacts to changes in soil conditions, always maintaining the set optimum row unit pressure.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

Auto singulation monitors and optimizes

With automatic motors on each row unit, seed singulation is continuously monitored and optimized. This saves time and increases the productive time in the field.

Full control at your fingertips

The iPad-based control system, Väderstad E-Control, wirelessly delivers data about each seed that travels through the planter, including seeding quality, skips, doubles, spacing and rate.

You benefit from user-friendly remote setup and calibration, as well as easy, real-time monitoring and control.

Through the iPad, you can download the most recent software updates, allowing your system to always stay current with future developments.

QuickStart

See our QuickStart videos for your Tempo L.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

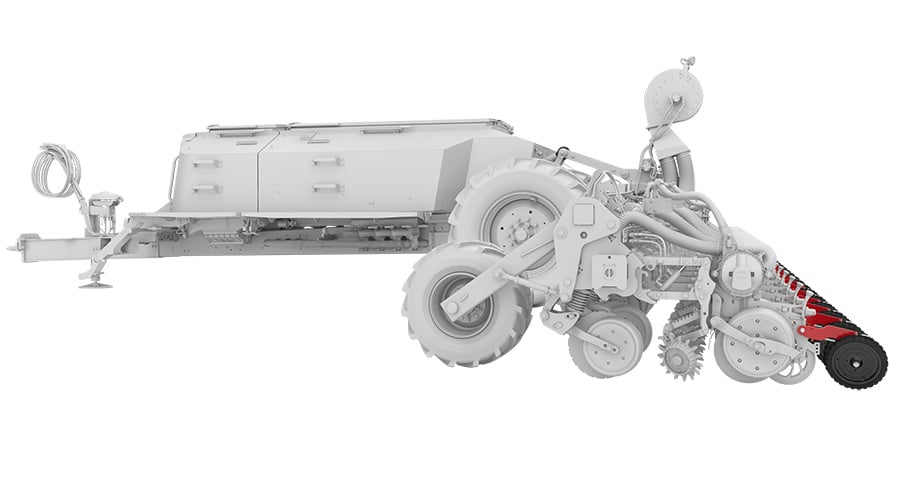

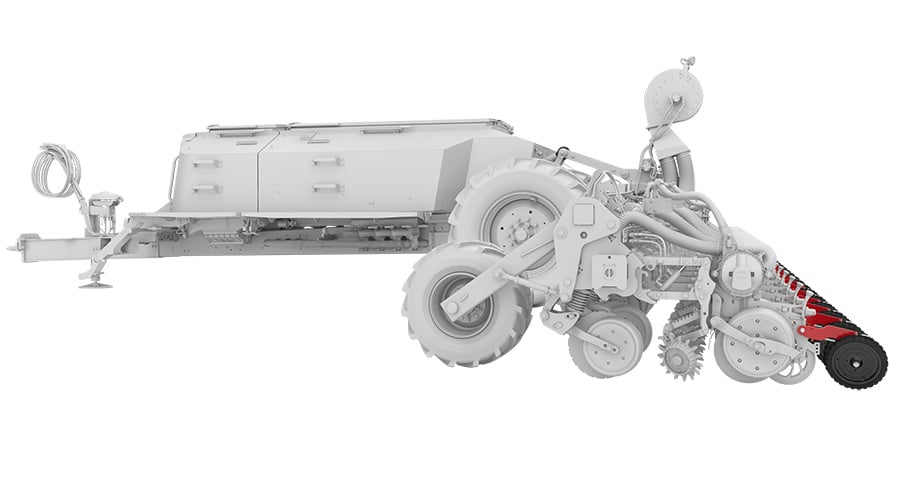

Zone 1 - Fertilizer placement (option)

To fit different farming needs, the Tempo L with Central Fill is available with or without fertilizer. The seed-only models are equipped with a central 85-bushel hopper for seed, while the seed and fertilizer models utilize a 204-bushel hopper with two compartments: 62 bushels for seed and 142 bushels for fertilizer.

The electric driven Fenix III can adapt to varying field conditions by applying fertilizer at variable rates. The high capacity fertilizer coulters maintain high precision even at high speeds.

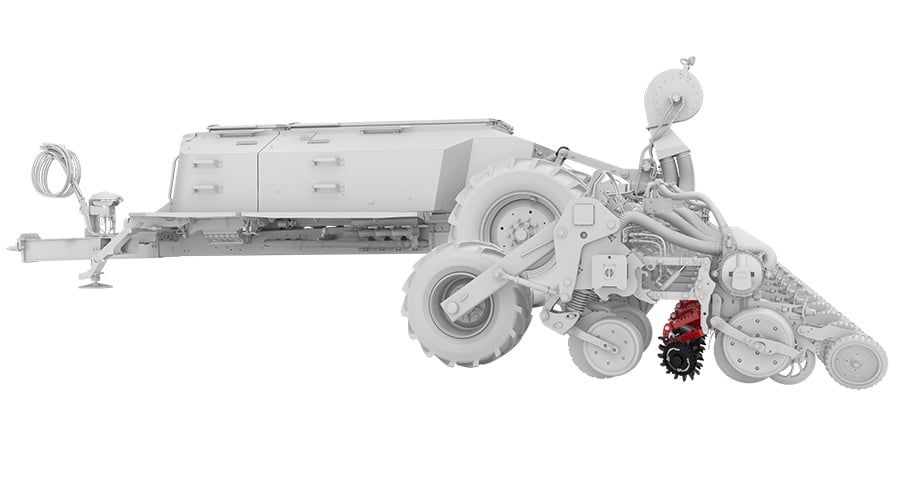

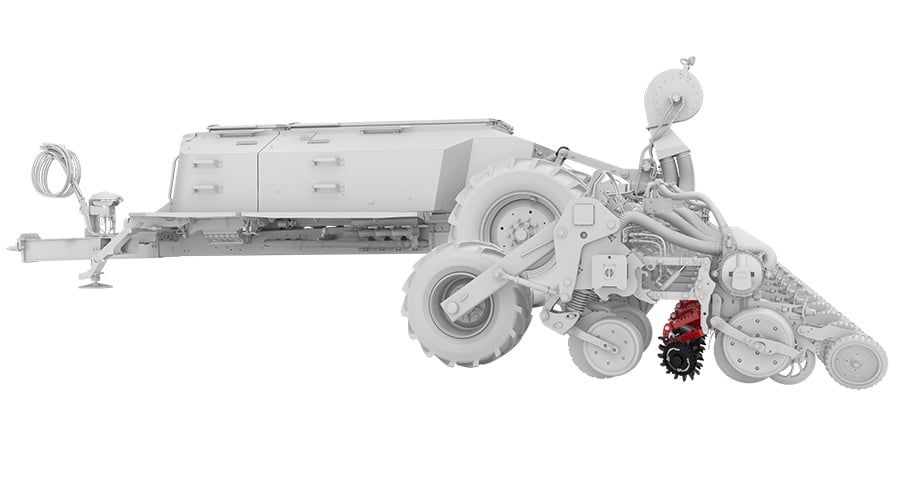

Zone 2 - Row cleaners (option)

Row cleaners are optional on the Tempo. They're used to remove crop residue, clods and rocks ahead of the disc openers. The need to use row cleaners is much higher when planting into no-till conditions or other fields with large amounts of residue.

Zone 3 - Seed placement

With the Tempo, planting can be done at very high speeds without compromising precision and accuracy. The seed meters ensure perfect placement for every seed, which is key to maximizing yield.

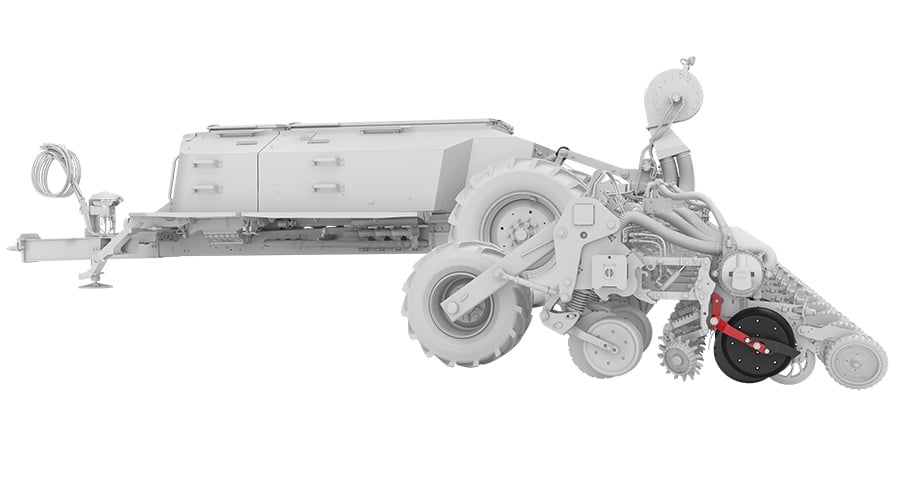

Zone 4 - Closing

After the seed is planted, the closing wheels cover the seed trench, creating perfect conditions for germination. Several industry-standard, third-party closing wheel solutions can also be used, depending on the needs of each farm.

Gallery

Specifications

| Number of rows | 8 | 12 | 16 | 18 | 24 | 32 |

| Row spacing, in (mm): |

30 (700-800)

|

18, 20 (450-508) |

30 (700-800) |

18, 20 (450-508) |

18, 20, 22 (450-559) |

15 (375-381) |

|

22, 30 (559-800) |

||||||

| Frame width: ft. (m) | 19' 7" (6.0) | 19' 7"-31' 2" (6.1-9.8) | 35' 4"-39' 4" (10.8-12.0) | 27' 2"-32' 2" (8.3-9.8) | 35' 4"-39' 4" (10.8-12.0) | 39' 7" (12.1) |

| Working width: ft. (m) | 18' 4"-21' (5.6-6.4) | 17' 7"-31' 6" (5.4-9.6) | 36' 9"-40' (11.2-12.2) | 26' 6"-29' 9" (8.1-9.1) | 35' 5"-40' (10.8-12.2) | 39' 4"-40' (12.0-12.2) |

| Transport width: ft. (m) | 9' 10" (3) | 9' 10" (3) | 9' 10"-11' 2" (3.0-3.4)*** | 9' 10"-11' 2" (3.0-3.4)*** | 9' 10"-11' 2" (3.0-3.4)*** | 12' 8" (3.85) |

| Transport height: ft. (m) | 13' 1" (4) | 13' 1" (4) | 13' 1" (4) | 13' 1" (4) | 13' 1" (4) | 13' 11" (4.25) |

| Weight Seed only version: lbs. (kg)* | 13,448-15,212 (6,100-6,900) | 14,771-16,975 (6,700-7,700) | 16,534-18,960 (7,500-8,600) | 16,534-19,400 (7,500-8,800) | 18,960-21,605 (8,600-9,800) | 24,250-28,219 (11,000-12,800) |

| Weight Combi version: lbs. (kg)* | N/A | N/A | 25,353-26,676 (11,500-12,100) | N/A | 30,424-31,526 (13,800-14,300) | N/A |

| Weight transfer | Mech-/Hyd | Mech-/Hyd | Hyd | Hyd | Hyd | Hyd |

| Volume seed hopper: Bushel (L) | 85 (3,000) | 85 (3,000) | 62/85 (2,200/3,000) | 85 (3,000) | 62/85 (2,200/3,000) | 85 (3,000) |

| Volume fertilizer hopper: Bushel (L) | N/A | N/A | 142 (5,000) | N/A | 142 (5,000) | N/A |

| Hydraulic requirements (Seed only) | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** | 5 DA + 2 FR** |

| Hydraulic requirements (Combi) | N/A | N/A | 6 DA + 2 FR** | N/A | 6 DA + 2 FR** | N/A |

| Oil flow requirements: gpm (L/min) | 29-34 (110-130) | 29-53 (110-200) | 37-61 (140-230) | 37-53 (140-200) | 37-69 (140-260) | 37-53 (140-200) |

| Draught requirements from (hp) | 150-200 | 200-300 | 300-350 | 300-350 | 300-350 | 350-400 |

*Weight min-max depends on equipment. Empty hoppers.

**One return line (case drain) without back pressure (max 36 psi/2.5 bar) for draining of fan motors.

***11' 2" (3.4m) transport width with dual wheels.

Search product documents

Are you looking for product documents such as Manuals, Spare part books or Quick starts for your Väderstad product? Manuals and Spare Part books are available for all products we produced since 1962.