Väderstad breaking new ground with SeedEye

Väderstad is presenting an entirely new and unique technology in the form of the SeedEye seed counter, for seed drills Rapid A 400-800S. Farmers can now easily set the number of seeds per square metre without needing to perform calibration tests. SeedEye provides additional functionality for Väderstad’s established control system E-Control.

“Fast and exact determination of seed volume has been on farmers’ wish lists for decades,” says Crister Stark, Chairman of the Board at Väderstad. “Väderstad can now fill this need though SeedEye, an entirely new and unique solution.”

Seed counting sensor for precision drilling - SeedEye

1.The operator sets the seed volume per square metre from the control panel, eliminating normal calibration testing, saving time and effort

2.The operator has full control of the sowing process via the iPad display at the control panel. If a seed coulter deviates from the preset permitted variation an acoustic alarm is sounded and the faulty seed coulter is marked in red on the display

3.No resetting of the seed drill is necessary between different crops. SeedEye handles this automatically by the operator changing the value on the display, which increases efficiency

4.Increased seeding reliability as well as increased operator comfort due to the operator having an overview and control as never before

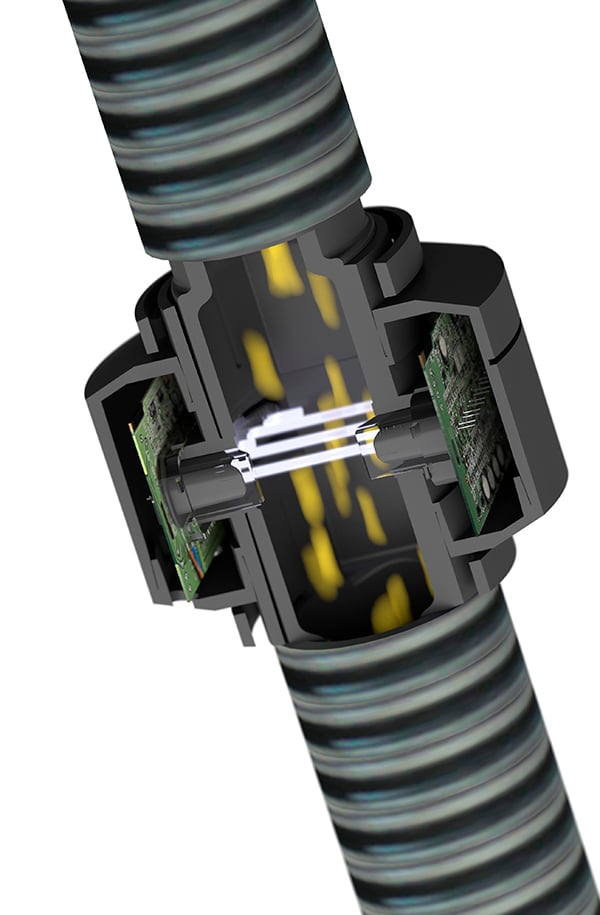

Sensors count total seeds

Sensors are located in the seed hoses. The seeds flow through the sensors, which are equipped with six optical transistors. These are illuminated with infrared light. When a seed passes a ray of light, the light is very briefly interrupted and the optical transistor registers a break in the flow of light.

The total number of breaks is registered and processed, enabling the seed volume to be specified with high accuracy. The sensors count rape with approximately 99 percent accuracy. The value for wheat and other grains is approximately 98–99 percent at 250 seeds per second. The system automatically sets accuracy and compensates for the dust and residue that can gather in the sensors.

“Counting seeds is more exact than by calculating quantities based on seed weight,” says Crister Stark. “The system has been developed as a direct response to farmers’ needs to predict total plants per square metre.”

The operator sets the seed volume per square metre

The operator sets the desired seed volume per square metre on an iPad without needing to climb down from the tractor to perform a conventional calibration test. The seed drill’s radar measures seed drill speed and E-Control continuously calculates how well the “set point” for the desired volume of seeds per square metre agrees with the actual feed value as attained via SeedEye. The feed, which is electrically powered, is constantly regulated to produce the desired seed volume.

Easy to vary seed volume

If the operator wants to change the seed volume per square metre, the change is entered on an iPad where the volume is shown on the display. This is easily accomplished with preset steps of, for example, 10 percent. The seed drill immediately sets the desired seed volume per square metre regardless of tractor speed and displays the actual value. The system works equally well with or without ISOBUS.