Designed, tested and manufactured by Väderstad

The wear parts are the most critical components of your machine. Their quality and design determine much of the machine’s performance in the field. They need to have excellent agronomic properties, be durable and fit perfectly on Väderstad’s machines. That’s why we manufacture almost all our Genuine Parts ourselves.

Designed for optimum yields

Our engineers are constantly working on improving existing wear parts and developing new innovations – all aimed at increasing your yields and cutting the cost per hectare. Over the years Väderstad has invented countless wear parts that have revolutionised farming, not least the Marathon points and CrossCutter Disc. However, the standard points have also been improved over time, for even longer durability and a more consistent result over the whole field. Väderstad is a driving force in the industry when it comes to design and innovation.

Tested for all conditions

Before a wear part is launched onto the market, it is tested countless times in the lab, out in the field and in the toughest and stoniest conditions. Durability over time and the capacity to handle hard knocks from large stones, for example, are both put to the test. Because we manufacture almost all of the parts ourselves, we can also test random samples during manufacture to guarantee consistently high quality on the production line.

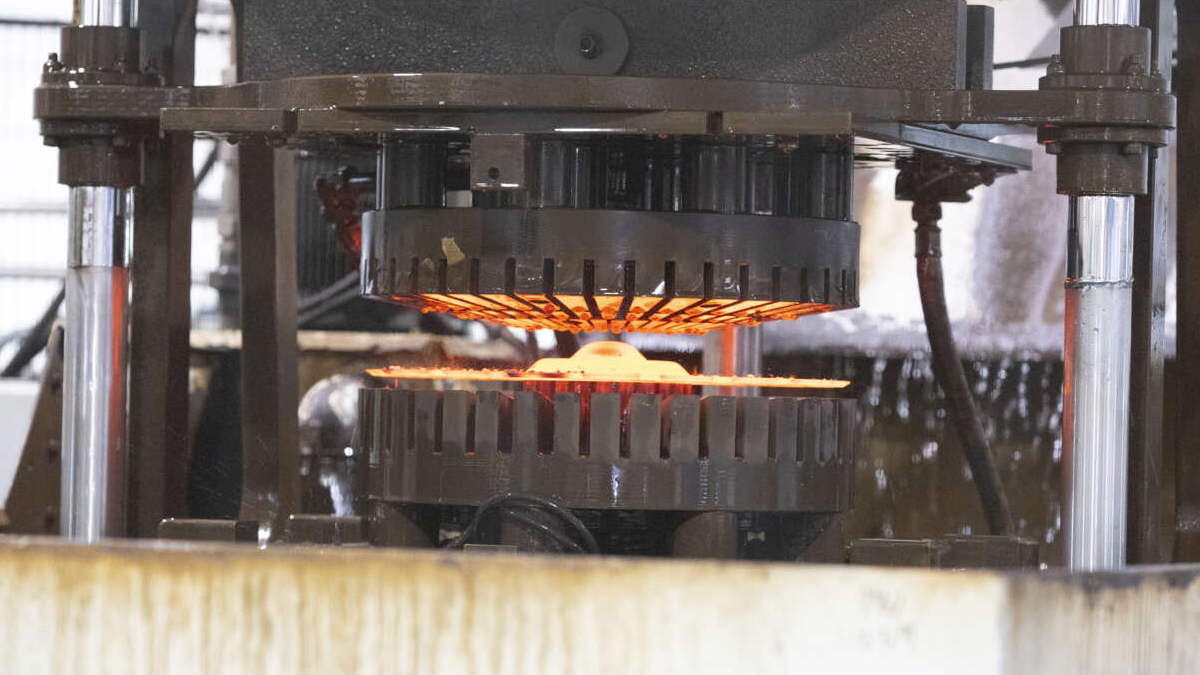

High-tech manufacture and press hardening

The majority of Väderstad’s Genuine Parts are made by the wholly owned subsidiary Väderstad Components. The manufacturing process begins in one of our laser machines and then continues on to press hardening, where the steel is given its shape and hardness all at the same time. Press hardening of steel is about getting the right balance between time and temperature – needless to say, our engineers lead the world on this score.

A lab that offers huge potential

The lab is equipped to conduct the various tests that are necessary in pursuit of the optimum mechanical properties. The purpose of the business is threefold: development, investigation and follow-up. The development work focuses on materials or material processes that improve performance, reliability and/or cost-efficiency. Väderstad has long-established partnerships with higher education institutions such as Linköping University and KTH Royal Institute of Technology. The lab expands the potential of these partnerships, since much of the experimental work can be conducted on site, close to the production.