Spirit seed drills

High precision – perfect emergence

The pneumatic seed drill Spirit carries out levelling, seedbed preparation, reconsolidation, seeding and pressing in one pass. It is known to provide impressive precision at high working speeds on the field. Thanks to the individual row depth control, Spirit always places the seed at the intended seeding depth. You benefit from an even emergence over the entire field.

Accept Cookies to Continue

You need to accept cookies in order to view this feature. Click here to change your consent.

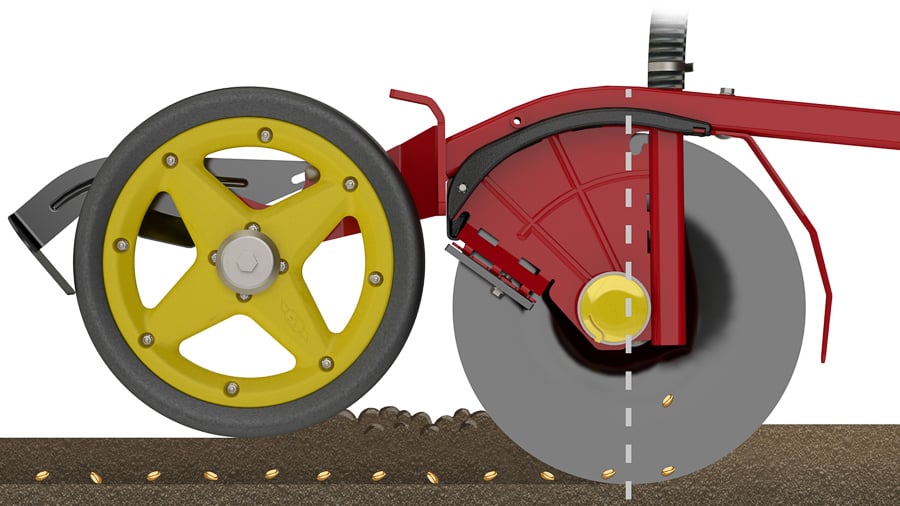

High precision seed coulters

To ensure a firm seedbed, large packer wheels consolidate the soil prior to seed placement. Each individual seed coulter has a wide coulter press wheel. This allows the seed coulters to respond to any irregularities or soil variations on the field, thereby ensuring the working depth is constantly maintained. The generous diameter of the coulter press wheel, further results in a smooth ride with minimal impacts from vibrations, thereby increasing precision at high speed.

Impressive seed placement

To achieve the perfect seed placement in lighter soils or at shallow drilling, Spirit is equipped with double seed discs.

The large diameter seed discs offer a smooth ride, whilst the robust V-55 Swedish steel provides an extremely long working life.

To adapt to varying soil conditions, the coulter pressure can be altered from the cab on the move.

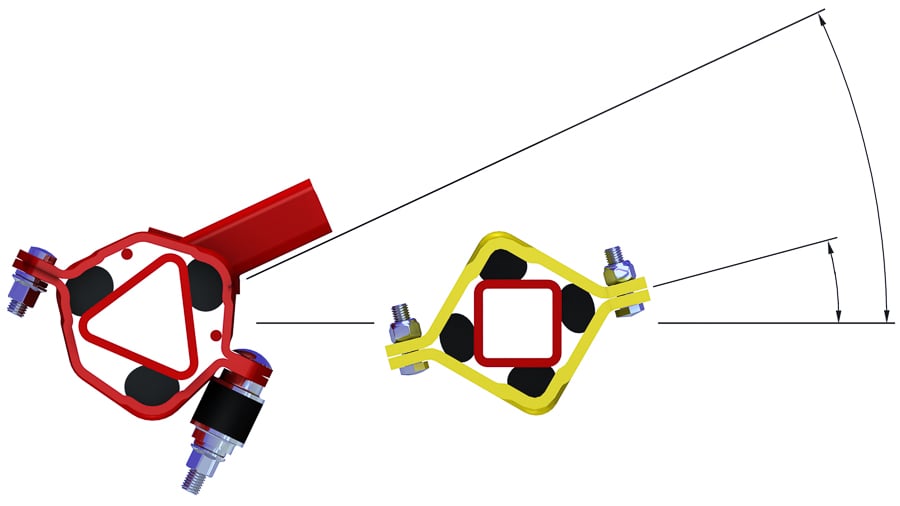

TriForce

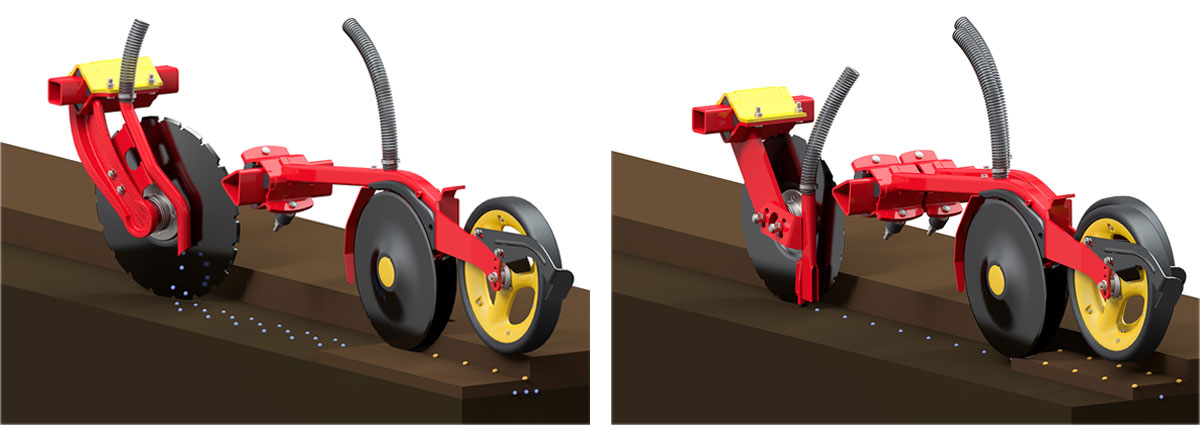

TriForce is Väderstad’s unique coulter suspension doubling the coulters contour movement compared to a conventional four bar rubber suspension.

This gives perfect seed placement on uneven ground, such as wheel tracks or undulating fields.

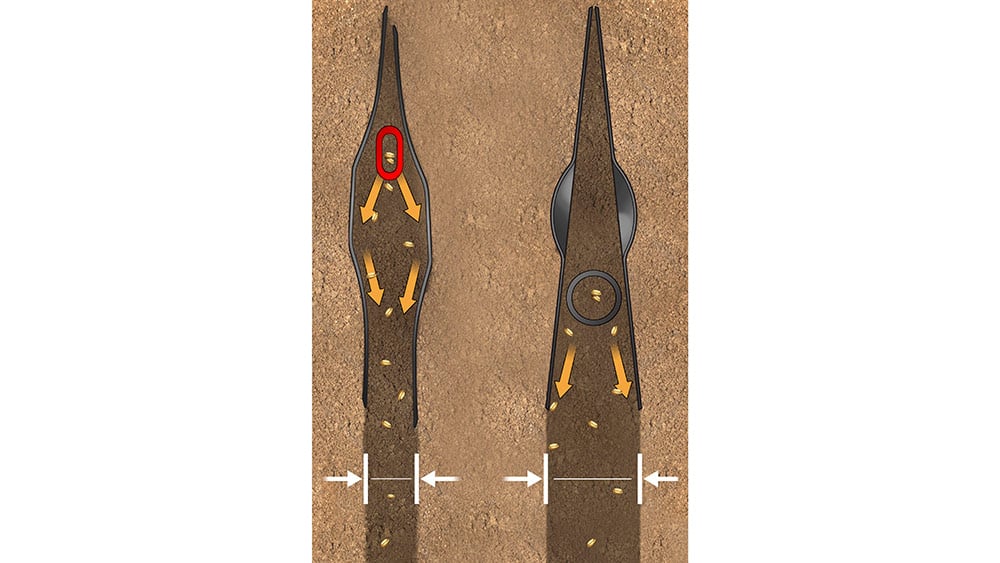

OffSet seed discs

To provide an aggressive working angle but with maximum penetration force, the seed discs are mounted in an OffSet position. Spirit is able to reach the desired working depth irrespective of soil type or conditions on the field.

Due to the discs design the aggressive working angle of the seed discs is maintained over time, thereby maximising precision. Non-offset discs open up with wear allowing soil to enter, this disrupts the seed distribution and reduces precision.

Conical disc shape

The seed discs have a conical shape, this shape creates a narrow seed slot with minimal disruption to the soil.

This results in lower draught requirement and an increased ability to handle crop residues. Together with the OffSet seed disc, seed depth is maintained with low coulter pressure.

Seed tube positioning

Seed is released in front of the seed discs centre, this enables the seed to benefit from the rotational movement of the disc.

The rotation of the seed disc helps place the seed in the bottom of the seed slot, enabling immediate access to moisture. This system does not require a seed firmer which lowers wearing part costs.

Important details like these together form Spirit's signature - an exact seed placement and a perfect emergence

125mm row spacing for maximum yield

A rapid and even emergence provides the crop with considerably higher competitiveness against weeds, this is especially important as more herbicide resistant weeds are on the increase. Research show that 125mm row spacing result in 20% less weeds than 150mm. A narrow row spacing allows for a larger seed spacing, thereby lowering the fungi pressure. The rapid and even emergence leads to lower evaporation, at a time when the access to moisture is most crucial.

Front tools without compromises

To effectively prepare the seedbed, Spirit is equipped with heavy-duty front tools. The individually mounted discs provide perfect precision and throughflow. The conical shape of the discs create a high degree of fine tilth, important for the seed-to-soil contact. The front tools can be adjusted from the cab on the move. Since the front tool is mounted on a parallel linkage, an even working angle is guaranteed irrespective of working depth. For levelling an individually adjustable CrossBoard can be mounted ahead of the disc tool.

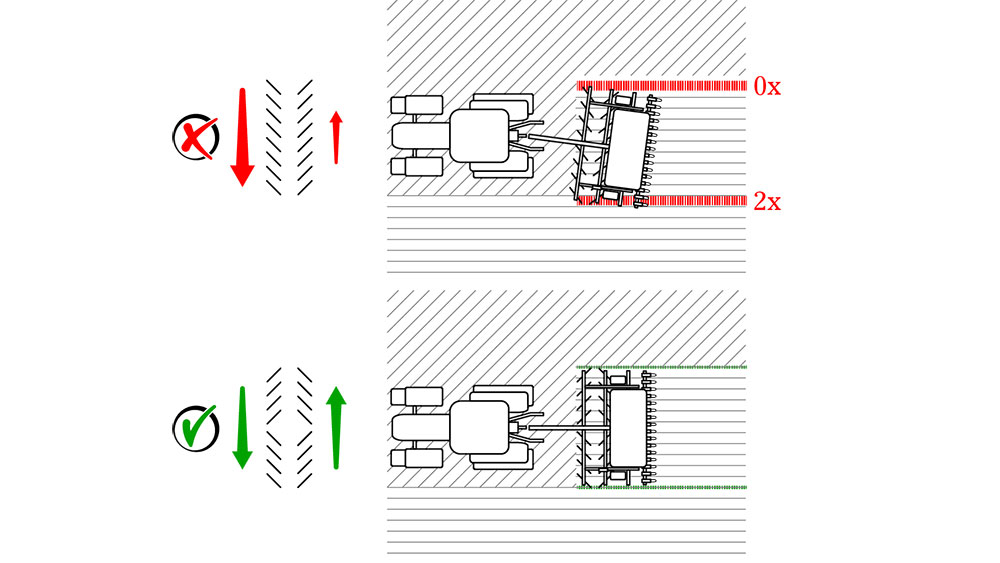

X-disc – To reach full potential

To gain full control, it is very important that the seed drill does not alter from its straight track behind the tractor. Something that is further essential in hilly conditions.

The x-disc setup of the front tool keeps the machine straight behind the tractor.

The x-disc is a natural component for modern farming and a crucial factor to reach the full potential of a GPS- or RTK-system.

The packer wheels create an even seedbed

To ensure a firm seedbed prior to seed placement, large packer wheels consolidates the soil between the front tool and seed coulters. This offers great advantages in lighter soil, as well as in fields where the soil is loose as an effect of a deep cultivation or a cultivation with insufficient reconsolidation.

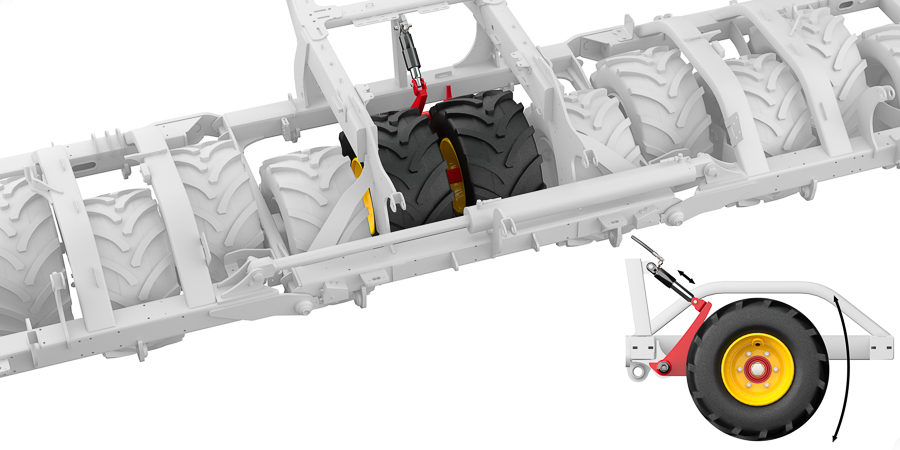

Hydraulically adjustable middle packer

To ensure the same conditions for each seed, Spirit is equipped with a hydraulically adjustable middle packer that runs between the tractor wheels.

You benefit from an even emergence over the entire working width.

OffSet saves fuel

OffSet means that every second packer wheel is displaced 250mm backwards on a separate axle. According to studies, OffSet minimises bulldozing and lowers the draught requirement by 25%. An additional advantage is that the design is less susceptible to vibrations, resulting in higher drilling accuracy.

Combi-drilling secures success

Nutrient placement during drilling provide a fast and reliable fertilisation effect. Since the fertiliser is placed in moist soil there is less dependence on rain, while placement also gives high yields and better nutrient use efficiency. To match different farming needs, the combi-version Spirit is available with two different fertilising methods – FIX or Nordic.

Long working life

Spirit is designed to achieve a long working life and low operating costs. Maintenance-free bearings, long-life joints and few greasing points, results in a low service requirement and minimal downtime on the field.