QuickStart videos

See our QuickStart movies for your Spirit.

3m

125mm

>100hp

2800 litre

Spirit R 300S is a pneumatic seed drill, available with 3 metre working width. Spirit R 300S has all the benefits of a small seed drill, while taking advantage of the innovative technology and high precision from the larger models. You benefit from high capacity, precision, user-friendliness and reliability on the field.

The pneumatic seed drill Spirit carries out levelling, seedbed preparation, reconsolidation, seeding and pressing in one pass. It is known to provide impressive precision at high working speeds on the field. Thanks to the individual row depth control, Spirit always places the seed at the intended seeding depth. You benefit from an even emergence over the entire field.

Spirit R is equipped with the user-friendly and easily accessible metering system Fenix III. It is able to handle seed rates down to 1kg per hectare, while also enabling high doses, never limiting capacity.

One important feature of Fenix III is the soft rotor that seals the system and lowers the air requirement, in turn saving diesel.

Fenix III achieves great precision which leads to an even emergence.

The 2800 litres plastic seed hopper is designed to provide a low filling height with large opening.

The working platform is positioned on the side of the seed hopper for easy access when filling.

The high positioned integrated fan reduces dust intake and increases drilling precision.

The active coulter pressure ensures an impressive depth control. With sensors in the hydraulic system, the machine immediately compensates for any rise or dip in the field.

The coulter pressure is maintained at the pre-set value, irrespective of coulter working angle in relation to the rest of the machine.

You benefit from an even emergence over the entire field.

Seed is metered by two Fenix III units, each metering one half of the machine, this enables half machine shut-off from the cab.

Farmers who regularly use half machine shut-off appreciate the fact that they can save up to 5 % of seed, at the same time avoiding double drilling and uneven crops.

You need to accept cookies in order to view this feature. Click here to change your consent.

Väderstad SeedEye is a unique system for seed counting and seed monitoring. With SeedEye farmers can easily set the number of seeds per square metre, without the need for calibration. SeedEye ensures excellent seeding results with full control.

To optimise the operations at the headland, Spirit R is equipped with automatic headland sequence control. The system automatically lifts and lowers the front tools and seed coulters in sequence.

When entering the field the system lowers the front tool into the soil before the seed coulters.

Even crop establishment is achieved by eliminating double drilling or overworked headlands. Further, the system enables drilling of the headland first, without disrupting the result when drilling the rest of the field.

The pivot packer consolidates the soil between the tractor wheels enabling each seed to have the same conditions for germination.

The pivoting function minimises soil drag on the headland.

The pivot packer reduces the turning radius, shortening headlands and maximising the full potential of the field.

Spirit R 300S is equipped with the iPad-based control system Väderstad E-Control.

In addition to an extensive control and monitoring of the seeding process, the control system offers the possibility to adjust the working depth of the front tool, the seed coulters as well as the hydraulic following harrow, while driving on the field.

User-friendliness, state of the art graphics, cost-effectiveness and an easy to update system are some of its main advantages.

You need to accept cookies in order to view this feature. Click here to change your consent.

Before drilling, the soil is consolidated by the tractor wheels. The pivot packer on Spirit R ensures that the same reconsolidation is exerted on areas between tractor wheels.

Depending on the front tools, Spirit can be adapted to varying conditions. The working depth and intensity of the front tools can be easily adjusted from the tractor cab.

To ensure a firm seedbed prior to seed placement, large packer wheels consolidates the soil between the front tool and seed coulters. This offers great advantages in lighter soil, as well as in fields where the soil is loose as an effect of a deep cultivation or a cultivation with insufficient reconsolidation.

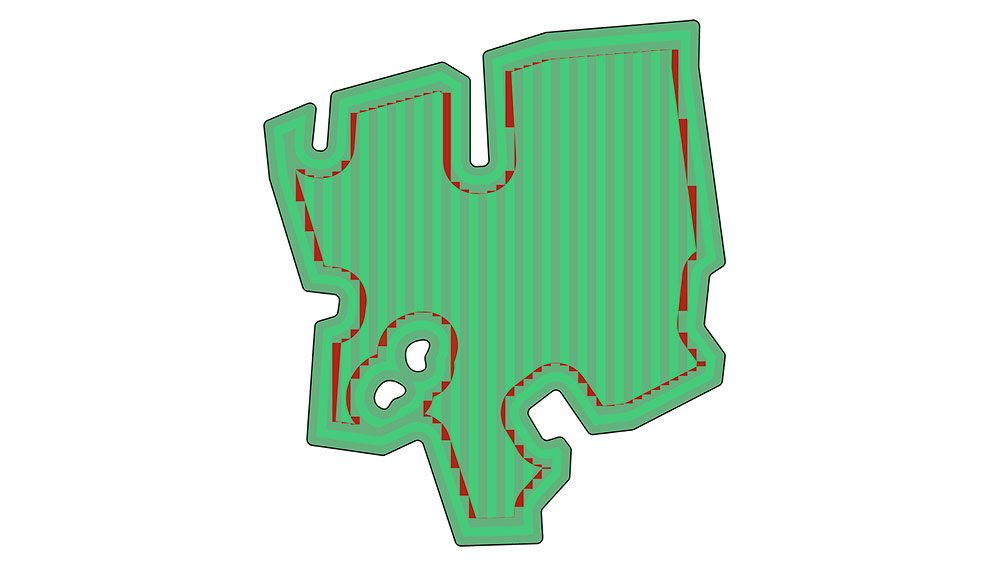

Spirit R has 380mm large discs for high speed accuracy. The OffSet discs move the soil to the side and place the seed in the bottom of the seed furrow. The soil falls back behind the discs and covers the seed with fine soil. The seed coulter pressure is up to 80kg to ensure a good penetration. The unique TriForce rubber suspension gives a supreme ability to follow ground contour.

Each individual seed coulter has a wide coulter press wheel. This allows the seed coulters to respond to any irregularities or soil variations on the field, thereby ensuring the working depth is constantly maintained. The generous diameter of the coulter press wheel, further results in a smooth ride with minimal impacts from vibrations, thereby increasing precision at high speed.

The following harrow is positioned to run in-between the seed rows, so there is no risk of disturbing shallow-drilled seeds.The following harrow creates a loose evaporation barrier to preserve moisture and prevents capping after heavy rain.

| Spirit R | 300S |

| Metering | Electrical |

| Working width (m) | 3,0 |

| Transport width (m) | 3,0 |

| Transport height (m) | 2,65 |

| Transport length (m) | 8,9 |

| Basic weight (kg) | 4000 |

| Volume seed hopper (l) | 2800 |

| Number of seed coulters | 24 |

| Row spacing seed (mm) | 125 |

| Number of fertiliser coulters | - |

| Row spacing fertiliser (mm) | - |

| Seed coulter pressure max (kg) | 80 |

| Seed disc diameter (mm) | 380 |

| Recommended working speed (km/h) | 8-14 |

| Wheel dimension (transport wheels) | 400/55-15,5 |

| Hydraulic requirement | 3 DA + FR |

| Draught requirement from (hp) | 110 |

| Oil capacity for hydraulic fan (l/min) | 40 |

| Väderstad has made every attempt to accurately portray our product lineup. However, due to our commitment to continually innovate our technologies to provide our customers the best possible products, some products may not be manufactured as shown on this site. Exact specifications for each product will be confirmed at the time of ordering. |

| DA = Double acting | FR = Free return |