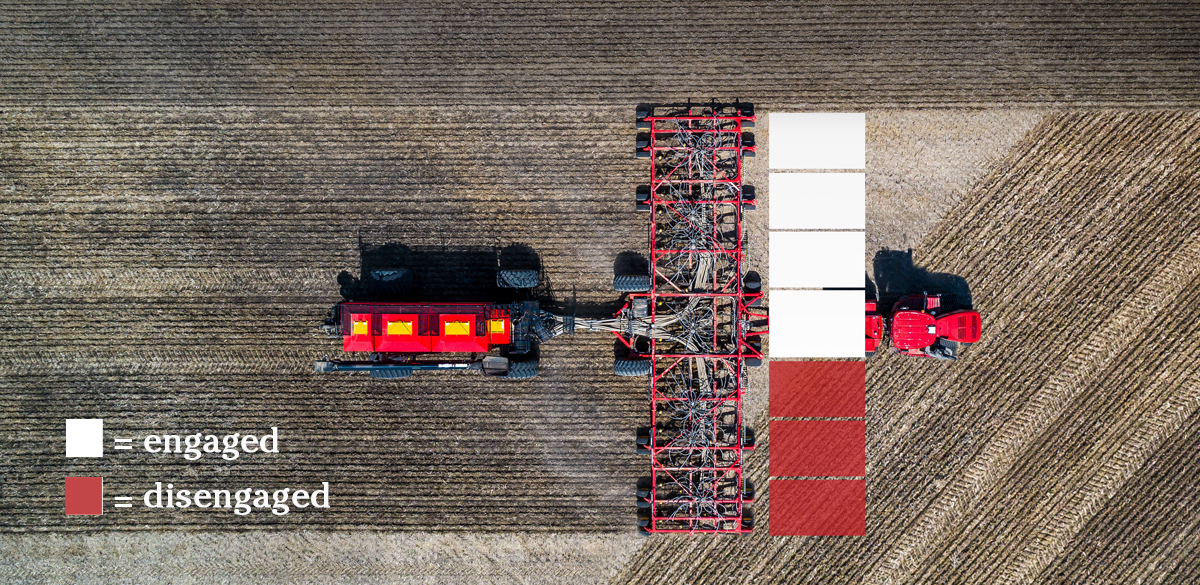

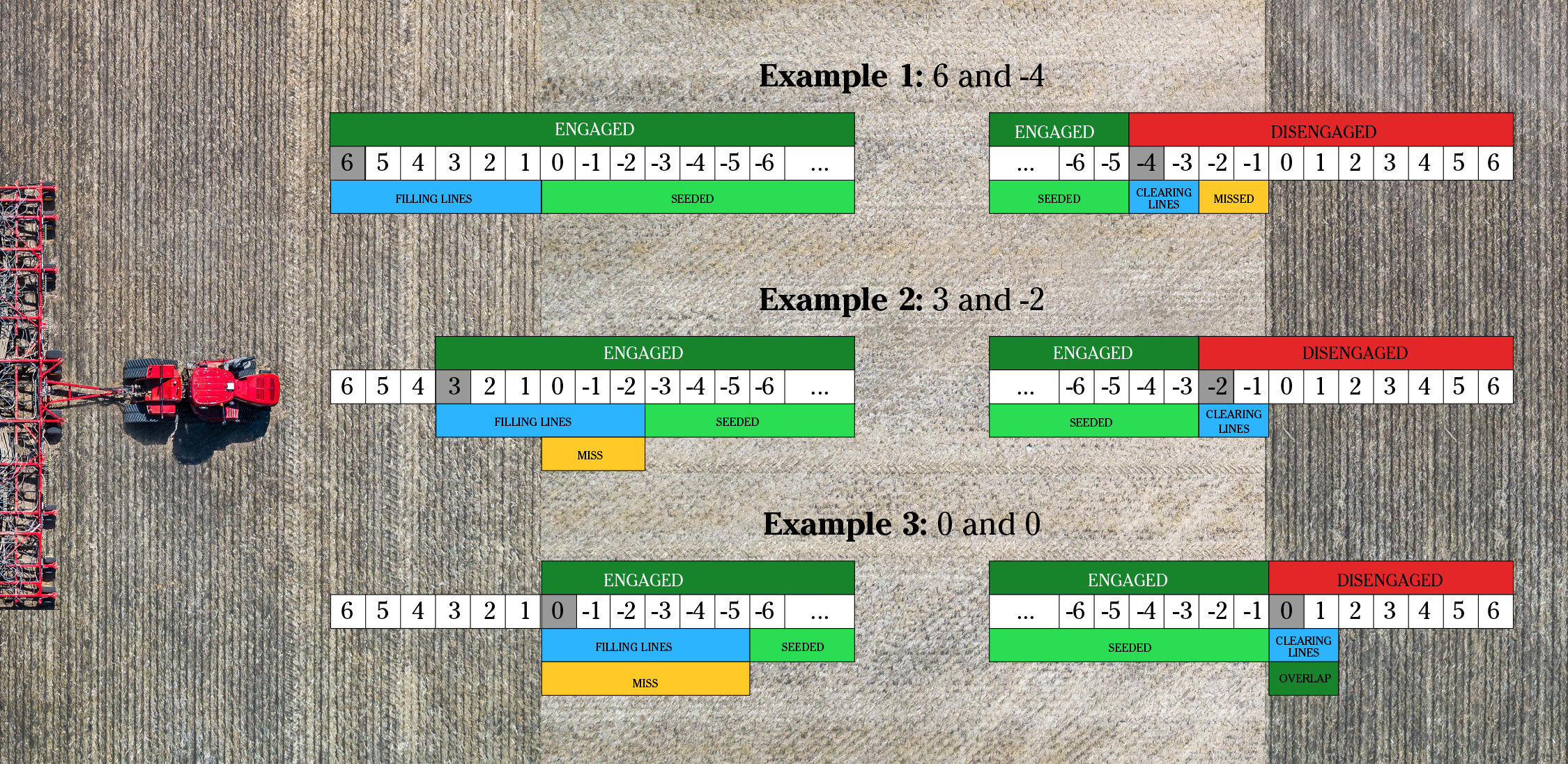

Lookaheads are used by the system to compensate for real world conditions that cause non-ideal behaviour. This includes the time it takes for product to travel down the seed tube and the time it takes for the openers to fully engage.

Engage Lookaheads

Engage lookaheads compensate for the amount of time between when a section is engaged and when product begins to hit the ground. They can be configured from 0 to 30 seconds, however in most cases they will be less than 10. Larger lookahead values cause the sections to begin applying product earlier yielding more overlap.

Once a section has begun to engage, it cannot be disengaged until its lookahead period has expired. For

example, if a section with an engage lookahead of 15 seconds begins to engage, but then encounters seeded area, it will remain engaged for at least 15 seconds. The only exception to this rule is that a section may disengage early if it leaves the field boundary.

Disengage Lookaheads

Disengage lookaheads compensate for the amount of time between when a section is engaged and when product stops hitting the ground. They can be configured from -30 to 30 seconds, however in most cases they will be less than 10. Larger disengage lookahead values cause the

sections to disengage later yielding more overlap.

Product vs. Opener Lookaheads

There are two main sources of mechanical delay that engage/disengage lookaheads account for:

• the time it takes for the openers to get into the ground

• the time it takes for the product to flow from the tank to the openers.

The iCon system accounts for each of these seprately. The user may set unique lookahead values for the

openers and each of the product tanks.

Note: Look ahead times are the responsibility of the operator and can vary due to machine, product and environmental conditions.

Read more