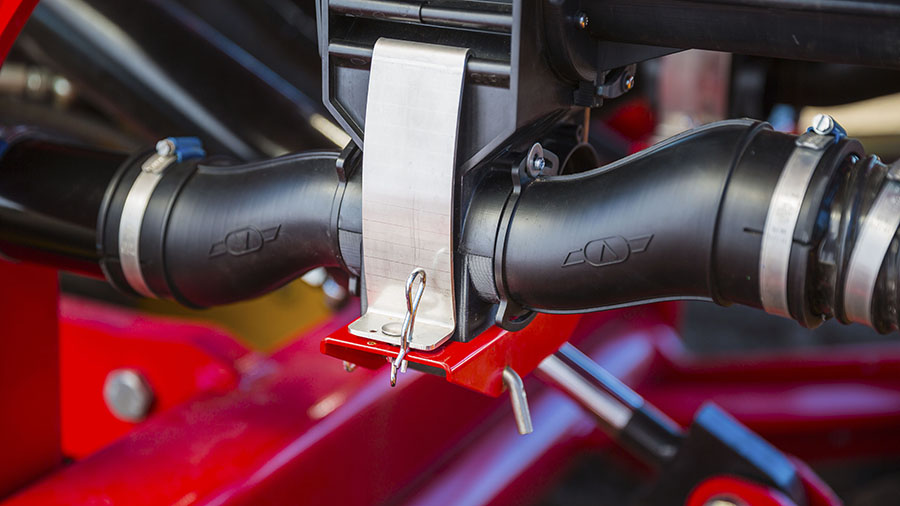

Cultivating front tool

Spirit R is equipped with System Disc Aggressive. The front tool with conical 450 mm discs provides intensive soil cultivation and produces an even soil structure. The machine runs straight behind the tractor as the discs are mounted in an X-pattern. The working depth can be easily adjusted from the operator panel.